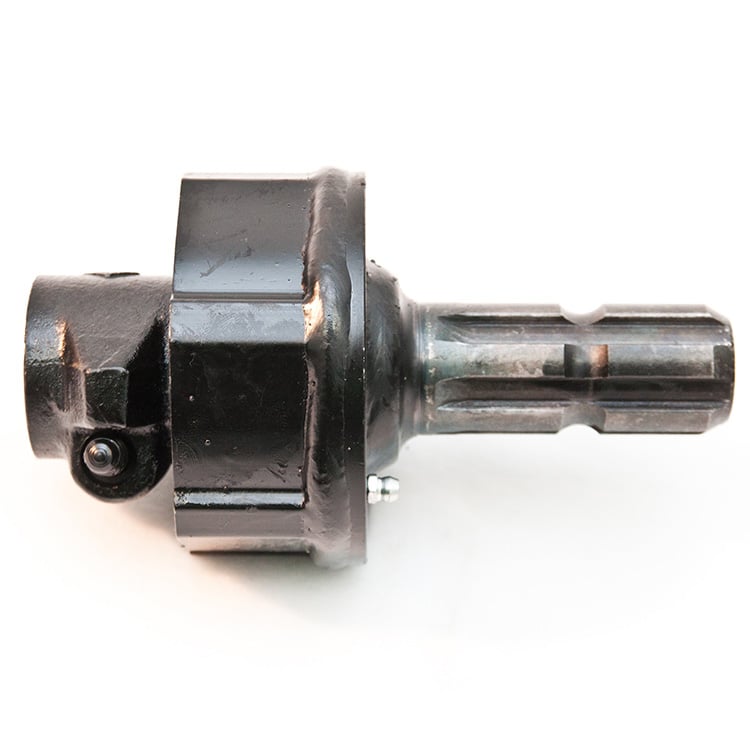

Product Description

PTO SHAFT

A triangular PTO shaft, or power take-off shaft, is a piece of equipment used to secure the tractor or other equipment. It has a safety shield on both ends to prevent injury. PTO shafts are similar to secondary shafts except that the front 1 is wider than the secondary one. This allows the secondary shaft to fit inside the front one. Unlike other parts, the triangular PTO shaft is shaped like a triangle. Its shields protect wholesome shafts and ensure a stable connection between the 2 machines. The triangular PTO shaft has a bearing and lubrication to reduce friction between the parts.

Whether you are plHangZhou to buy a new tractor or simply replace your old one, choosing a high-quality PTO shaft designed to last for years is important. Among the different types of PTO shafts, there are those made from steel, aluminum, or the tubes which are in various shapes such as star tubes, square tubes, triangular tubes, etc. However, before you choose any, make sure to learn more about each of these types and what their advantages and disadvantages are.

Triangular PTO Shaft Tubing

When it comes to purchasing Triangular PTO Shaft Tubing for your tractor, there are a few things to consider. While the size and shape of the shafting will vary, the cross-kit and bearing cap diameters are almost always uniform, so removing the cross-kit from the yoke may help you find the right PTO shaft. Using calipers is another helpful tool. You can use them to measure the end-to-end diameter of the tractor PTO shaft universal joint, as well as the internal diameter of the yoke ears. Then, match the measurements to the cross and bearing identification chart.

In addition to the Triangular PTO Shaft Tubing, other types of PTO Shaft Tubing are available for purchase. The triangular PTO shaft tubing is popular for constant-velocity PTO drivelines, while the lemon-shaped design is best for standard drivelines. On the other hand, a star-shaped profile tube is popular for its multiple contact faces.

Find the Right Triangular PTO Shaft Guard

You can find a triangular PTO shaft guard that fits your tractor in the following ways: the three-point attachment, the universal, or the triangular. This triangular PTO shaft can be customized to fit most tractors, including those with multiple extension parts. The unique plastic frame of the triangular PTO shaft is made with bearings so that it will fit the most common drivelines. This PTO shaft guard is sturdy enough for most applications. It will keep the triangular PTO shaft safe and prevent injuries while operating.

Replacing Triangular PTO Shafts

When your triangular PTO shaft becomes worn out or damaged, it is time to replace it. There are several different ways to do this. The cheapest option is to buy a new shaft. However, if you do not have time to find a new shaft, you may want to check out old threads or create a new one. Then, you will have a better chance of finding a unit that will work with your machine.

In order to replace your triangular PTO shaft, you will need first to determine the style and series of your old unit. Next, compare the shaft profile with the dimensions of your universal joint. Once you have this information, you can purchase the new triangular PTO shaft. If the PTO shaft does not fit your machine, you can contact us to help you determine the type of replacement unit you need.

The proper PTO drive shaft is essential in order to ensure smooth power transfer. When choosing a triangular PTO shaft, match the right 1 with your tractor’s driveline series. Incorrect measurements could cause damage to your tractor or attached implement. Ensure you follow the OEM specs when choosing a replacement triangular PTO shaft.

Triangular PTO Shaft Application

The triangular power take-off (PTO) shaft is an important part of a tractor’s driveline. It is responsible for transferring tractor power to attachments such as a rotary tiller, wood chipper, brush cutter, or hush hug. These types of triangular PTO shafts are commonly used on tractors and other farm and construction equipment. In addition, these types of shafts are also used in fertilizer spreaders.

Triangular PTO Shaft Maintenance

If your tractor has a heavy-duty tractor, check for a faulty shaft. Heavy equipment is subject to a lot of stress, so it’s important to take the proper precautions to protect it from damage. If you notice any of these problems, immediately stop your machine and call for help. Once the problem has been resolved, you can move on to the next phase of the job. However, you should note that there are some common machining specifications that should be checked before installing a triangular PTO shaft.

A PTO driveline is a crucial part of a tractor and should be properly maintained. Its main function is to transfer power from a tractor to the equipment. Without it, your tractor will not be able to drive. The PTO driveline is often overlooked during routine maintenance checks, but it is crucial to the proper operation of the tractor. There are many parts to a tractor’s PTO driveline, so understanding them will help you to maintain the tractor as efficiently as possible.

Triangular PTO shafts are used to secure a tractor and other equipment. The triangular PTO shaft has safety shields on both ends and a round hole in the middle. The 2 shafts are the same length and shape, but the front 1 is wider and has a slot in the middle for the secondary shaft. Some of these pieces can collapse into the center during movement, similar to a telescope. Various domestic and metric-shaped PTO shafts are also available.

MORE PRODUCTS

COMPANY INTRODUCTION

HangZhou CHINAMFG MACHINERY MANUFACTURE CO., LTD

Established in 2006, HangZhou CHINAMFG Machinery Co., Ltd is situated in the Shiliwang Industrial Zone of HangZhou, ZheJiang , China. With over a decade of experience, our company has grown to encompass more than 100 dedicated employees.

We specialize in the production of high-quality agricultural machinery and accessories, catering to the needs of global farming communities. Our focus spans farming machinery, planting equipment, harvesting solutions, and associated accessories, designed to complement tractors from leading manufacturers in China.

Our diverse product range includes PTO driveshafts, 12~160HP tractor disc harrows, disc ploughs, lawn mowers, rotary tillers, moldboard plows, deep plowing machines, and various agricultural machinery parts. From harrow blades to plough blades, soil-loosening shovels, rabble blades, and cane knives, our comprehensive selection meets global specifications, ensuring exceptional performance and reliable quality.

Our products have earned acclaim both domestically and internationally, with distribution across Europe, America, Africa, the Middle East, and Southeast Asia. Recognized as tax credit grade A enterprises and AA level bank credit companies for numerous years, we pride ourselves on maintaining the highest standards of integrity and product quality.

At HangZhou CHINAMFG Machinery Co., Ltd, we are committed to providing reliable product quality, outstanding after-sales service, and a streamlined production process. We welcome your inquiries, consultations, and investigations, adhering to the principles of honesty, fostering CHINAMFG relationships, and serving you with wholehearted dedication.

OUR FACTORY

FAQ

Q: Do you provide samples?

A: Yes, we could offer the sample.

Q: Can I customize the color & ODM/OEM?

A: Yes

Q: Are you the facroty?

A: Yes, we are the factory, you can require any color or logo for the product. we are specialized in various of Farm equipment.

Q: How long is your delivery time? What is your terms of payment?

A: Shipment time: 25-40 days after your payment

Shipment: By sea Loading port: HangZhou port, China

Destination port: To be advised

Payment: T/T (30%/70%)

Warranty: 1 year

Q:Spare parts available?

A:Yes, we pruduct the spare parts, so you can buy from us directly!

Q:I want to buy the other equipment, can you help?

A:I will suggest the manufacturer to you and help you analysis this supplier before you place your order.

I can also help to purchase the equipment you like.

Q: Why Hongri?

A: Comparing with our competitors, we have much more advantages

as follows:

1. More than 10 years in manufacturing farming machine

2. High-quality products at competitive prices

3. More Professional Sales staffs to guarantee the better service

4. More agri machines for your choice

5. More New products into your range to avoid price competition

6. Larger quantity production and shipment

7. More stick quality checking before shipment.

8. More reasonable after-sales service terms.

9. Lower repair rate and bad review rate.

10.Ensuring exceptional value for our customers

All the related products showed above were made by Hongri Factory, if you are interested in reselling our products, just contact

me while by below information:

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Type: | Pto Shaft |

|---|---|

| Usage: | Agricultural Machinery |

| Material: | 20crmnti |

| Power Source: | Gasoline |

| Weight: | 5+ |

| After-sales Service: | 1year |

| Samples: |

US$ 1/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

What factors should be considered when selecting the right PTO shaft for an application?

When selecting the right Power Take-Off (PTO) shaft for an application, several factors need to be considered to ensure optimal performance, safety, and compatibility. PTO shafts are crucial components that transmit power from a power source to driven machinery or equipment. Here are the key factors to consider when selecting the appropriate PTO shaft for an application:

1. Power Requirements: The power requirements of the driven machinery play a vital role in determining the appropriate PTO shaft. Consider the horsepower (HP) or kilowatt (kW) rating of the power source and ensure that the PTO shaft can handle the required power transmission. It is essential to match the power capacity of the PTO shaft with the power output of the power source to ensure efficient and reliable operation.

2. Speed and Torque Requirements: Consider the speed and torque requirements of the driven machinery. Determine the desired rotational speed and torque levels necessary for the equipment to operate effectively. Some applications require specific speed or torque ratios, while others may require variable speeds. Ensure that the selected PTO shaft can handle the required speed and torque range to provide the necessary power transfer.

3. Shaft Type and Design: Evaluate the type and design of the PTO shaft to ensure compatibility with the application. Consider factors such as the distance between the power source and the driven machinery, the need for angular misalignment, and the flexibility of movement required. Different shaft types, such as standard, telescopic, or Constant Velocity (CV) shafts, offer varying capabilities to accommodate different application requirements.

4. Safety Considerations: Safety is a critical factor when selecting a PTO shaft. Assess the safety features provided by the PTO shaft, such as protective guards, shear bolt mechanisms, or other safety devices. Protective guards should be in place to prevent accidental contact with the rotating shaft. Shear bolt mechanisms can protect the driveline components from damage in case of excessive torque or sudden resistance. Prioritize safety features that align with the specific hazards and risks associated with the application.

5. Application Specifics: Consider the unique requirements of the application. Factors such as the type of machinery, industry sector, environmental conditions, and operating conditions should be taken into account. For example, agricultural applications may require PTO shafts that can handle debris and dirt accumulation, while industrial applications may require PTO shafts with high corrosion resistance or special sealing to protect against contaminants.

6. Compatibility and Interchangeability: Ensure that the selected PTO shaft is compatible with the power source and the driven machinery. Consider factors such as the shaft diameter, spline size, and connection type. Check if the PTO shaft adheres to industry standards and if it can be easily interchanged with other compatible components in case of replacement or upgrading needs. Compatibility and interchangeability can simplify maintenance and reduce downtime.

7. Manufacturer and Quality: Choose a reputable manufacturer or supplier to ensure the quality and reliability of the PTO shaft. Look for manufacturers with a track record of producing high-quality PTO shafts that meet industry standards and regulations. Consider factors such as warranty, after-sales support, and availability of spare parts when making a selection.

By considering these factors, you can select the right PTO shaft that meets the power, speed, torque, safety, and application requirements. It is advisable to consult with experts, such as equipment manufacturers or PTO shaft specialists, to ensure an optimal match between the PTO shaft and the application.

How do PTO shafts enhance the performance of tractors and agricultural machinery?

Power Take-Off (PTO) shafts play a crucial role in enhancing the performance of tractors and agricultural machinery. By providing a reliable power transfer mechanism, PTO shafts enable these machines to operate efficiently, effectively, and with increased versatility. Here’s a detailed explanation of how PTO shafts enhance the performance of tractors and agricultural machinery:

1. Power Transfer: PTO shafts facilitate the transfer of power from the tractor’s engine to various agricultural implements and machinery. The rotating power generated by the engine is transmitted through the PTO shaft to drive the connected equipment. This direct power transfer eliminates the need for separate engines or motors on each implement, reducing complexity, weight, and maintenance requirements. PTO shafts ensure a consistent and reliable power supply, enabling agricultural machinery to perform tasks with optimal efficiency and effectiveness.

2. Versatility: PTO shafts provide tractors and agricultural machinery with increased versatility. Since PTO shafts have standardized dimensions and connection methods, a wide range of implements can be easily attached and powered by the same tractor. This versatility allows farmers to quickly switch between different tasks, such as mowing, tilling, planting, and harvesting, without the need for multiple specialized machines. The ability to use a single power unit for various operations reduces costs, saves storage space, and improves overall operational efficiency.

3. Improved Productivity: PTO shafts contribute to improved productivity in agricultural operations. By harnessing the power of tractors, agricultural machinery can operate at higher speeds and with greater efficiency compared to manual or alternative power methods. PTO-driven implements, such as mowers, balers, and harvesters, can cover larger areas and complete tasks more quickly, reducing the time required to perform agricultural operations. This increased productivity allows farmers to accomplish more within a given timeframe, leading to higher crop yields and improved overall farm efficiency.

4. Reduced Labor Requirements: PTO shafts help reduce labor requirements in agricultural operations. By utilizing mechanized equipment powered by PTO shafts, farmers can minimize manual labor and the associated physical effort. Tasks such as plowing, tilling, and harvesting can be performed more efficiently and with less reliance on human labor. This reduction in labor requirements allows farmers to allocate resources more effectively, focus on other essential tasks, and potentially reduce labor costs.

5. Precision and Accuracy: PTO shafts contribute to precision and accuracy in agricultural operations. The consistent power supply from the tractor’s engine ensures uniform operation and performance of the connected machinery. This precision is crucial for tasks such as seed placement, fertilizer or chemical application, and crop harvesting. PTO-driven equipment can provide consistent rotations per minute (RPM) and maintain the necessary operational parameters, resulting in precise and accurate agricultural practices. This precision leads to improved crop quality, reduced waste, and optimized resource utilization.

6. Adaptability to Various Tasks: PTO shafts enhance the adaptability of tractors and agricultural machinery to perform various tasks. With the ability to connect different implements, such as mowers, seeders, sprayers, or balers, via PTO shafts, farmers can quickly transform their tractors into specialized machines for specific operations. This adaptability allows for efficient utilization of equipment across different stages of crop production, enabling farmers to respond to changing needs and conditions in a cost-effective manner.

7. Enhanced Safety: PTO shafts contribute to enhanced safety in agricultural operations. Many PTO shafts are equipped with safety features, such as shields or guards, to protect operators from potential hazards associated with rotating components. These safety measures help prevent entanglement accidents and reduce the risk of injuries. Additionally, by using PTO-driven machinery, farmers can keep a safe distance from certain hazardous tasks, such as mowing or shredding, further improving overall safety on the farm.

8. Integration with Technology: PTO shafts can be integrated with advanced technology and automation systems in modern tractors and agricultural machinery. This integration allows for precise control, data monitoring, and optimization of machine performance. For example, precision guidance systems can be synchronized with PTO-driven implements to ensure accurate seed placement or chemical application. Furthermore, data collection and analysis can provide insights into fuel efficiency, maintenance needs, and overall equipment performance, leading to optimized operation and improved productivity.

In summary, PTO shafts enhance the performance of tractors and agricultural machinery by enabling efficient power transfer, increasing versatility, improving productivity, reducing labor requirements, ensuring precision and accuracy, facilitating adaptability, enhancing safety, and integrating with advanced technologies. These benefits contribute to overall operational efficiency, cost-effectiveness, and the ability of farmers to effectively manage theiragricultural operations.

Can you explain the different types of PTO shafts and their applications?

PTO shafts (Power Take-Off shafts) come in various types, each designed for specific applications and requirements. The different types of PTO shafts offer versatility and compatibility with a wide range of machinery and implements. Here’s an explanation of the most common types of PTO shafts and their applications:

1. Standard PTO Shaft: The standard PTO shaft, also known as a splined shaft, is the most common type used in agricultural and industrial machinery. It consists of a solid steel shaft with splines or grooves along its length. The standard PTO shaft typically has six splines, although variations with four or eight splines can be found. This type of PTO shaft is widely used in tractors and various implements, including mowers, balers, tillers, and rotary cutters. The splines provide a secure connection between the power source and the driven machinery, ensuring efficient power transfer.

2. Shear Bolt PTO Shaft: Shear bolt PTO shafts are designed with a safety feature that allows the shaft to separate in case of overload or sudden shock to protect the driveline components. These PTO shafts incorporate a shear bolt mechanism that connects the tractor’s power take-off to the driven machinery. In the event of excessive load or sudden resistance, the shear bolt is designed to break, disconnecting the PTO shaft and preventing damage to the driveline. Shear bolt PTO shafts are commonly used in equipment that may encounter sudden obstructions or high-stress situations, such as wood chippers, stump grinders, and heavy-duty rotary cutters.

3. Friction Clutch PTO Shaft: Friction clutch PTO shafts feature a clutch mechanism that allows for smooth engagement and disengagement of the power transfer. These PTO shafts typically incorporate a friction disc and a pressure plate, similar to a traditional vehicle clutch system. The friction clutch allows operators to gradually engage or disengage the power transfer, reducing shock loads and minimizing wear on the driveline components. Friction clutch PTO shafts are commonly used in applications where precise control of power engagement is required, such as in hydraulic pumps, generators, and industrial mixers.

4. Constant Velocity (CV) PTO Shaft: Constant Velocity (CV) PTO shafts, also known as homokinetic shafts, are designed to accommodate high angles of misalignment without affecting power transmission. They use a universal joint mechanism that allows for smooth power transfer even when the driven machinery is at an angle relative to the power source. CV PTO shafts are frequently used in applications where the machinery requires a significant range of movement or articulation, such as in articulated loaders, telescopic handlers, and self-propelled sprayers.

5. Telescopic PTO Shaft: Telescopic PTO shafts are adjustable in length, allowing for flexibility in equipment configuration and varying distances between the power source and the driven machinery. They consist of two or more concentric shafts that slide within each other, providing the ability to extend or retract the PTO shaft as needed. Telescopic PTO shafts are commonly used in applications where the distance between the tractor’s power take-off and the implement varies, such as in front-mounted implements, snow blowers, and self-loading wagons. The telescopic design enables easy adaptation to different equipment setups and minimizes the risk of the PTO shaft dragging on the ground.

6. Gearbox PTO Shaft: Gearbox PTO shafts are designed to adapt power transmission between different rotational speeds or directions. They incorporate a gearbox mechanism that allows for speed reduction or increase, as well as the ability to change rotational direction. Gearbox PTO shafts are commonly used in applications where the driven machinery requires a different speed or rotational direction than the tractor’s power take-off. Examples include grain augers, feed mixers, and industrial equipment that requires specific speed ratios or reversing capabilities.

It’s important to note that the availability and specific applications of PTO shaft types may vary based on regional and industry-specific factors. Additionally, certain machinery or implements may require specialized or custom PTO shafts to meet specific requirements.

In summary, the different types of PTO shafts, such as standard, shear bolt, friction clutch, constant velocity (CV), telescopic, and gearbox shafts, offer versatility and compatibility with various machinery and implements. Each type of PTO shaft is designed to address specific needs, such as power transfer efficiency, safety, smooth engagement, misalignment tolerance, adaptability, and speed/direction adjustment. Understanding the different types of PTO shafts and their applications is crucial for selecting the appropriate shaft forthe intended machinery and ensuring optimal performance and reliability.

editor by CX 2024-05-15

China factory High-Strength Tractor Part with Triangular Tube Design and 60kw Power Output pto shaft tubing

Product Description

Product Description

Company Profile

In 2571, HangZhou CZPT Machinery Co.,ltd was established by Ms. Iris and her 2 partners(Mr. Tian and Mr. Yang) in HangZhou city(ZHangZhoug province, China), all 3 Founders are engineers who have more than averaged 30 years of experience. Then because the requirements of business expansion, in 2014, it moved to the current Xihu (West Lake) Dis. Industrial Zone (HangZhou city, ZHangZhoug province, China).

Through our CZPT brand ND, CZPT Machinery delivers agricultural solutions to agriculture machinery manufacturer and distributors CZPT through a full line of spiral bevel gearboxes, straight bevel gearboxes, spur gearboxes, drive shafts, sheet metal, hydraulic cylinder, motors, tyre, worm gearboxes, worm operators etc. Products can be customized as request.

We, CZPT machinery established a complete quality management system and sales service network to provide clients with high-quality products and satisfactory service. Our products are sold in 40 provinces and municipalities in China and 36 countries and regions in the world, our main market is the European market.

Main Products

Packaging & Shipping

Certifications

FAQ

Q: Are you a trading company or manufacturer?

A: We’re factory and providing gearbox ODM & OEM services for the European market for more than 10 years

Q: Do you provide samples? is it free or extra?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: How long is your delivery time? What is your terms of payment?

A: Generally it is 40-45 days. The time may vary depending on the product and the level of customization.

For standard products, the payment is: 30% T/T in advance,balance before shipment.

Q: What is the exact MOQ or price for your product?

A: As an OEM company, we can provide and adapt our products to a wide range of needs.

Thus, MOQ and price may greatly vary with size, material and further specifications; For instance, costly products or standard products will usually have a lower MOQ. Please contact us with all relevant details to get the most accurate quotation.

If you have another question, please feel free to contact us.

| Application: | Machinery, Agricultural Machinery |

|---|---|

| Function: | Distribution Power, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase |

| Layout: | Straight or Spiral Bevel Gear |

| Hardness: | Hardened Tooth Surface |

| Installation: | Vertical Type |

| Step: | Single-Step |

| Samples: |

US$ 300/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Choosing the Right PTO Shaft For Your Tractor

There are a number of different PTO shaft types available for your tractor. These include the North American, German and Italian styles. They are also available in various series, each with different options for bearing diameter and cap-to-cap overall length. To choose the best shaft for your tractor, it’s important to know what kind of tractor you own and the type of PTO that you need.

IID shaft

When it comes to choosing the best IID shaft for your PTO, the selection process can be a challenge. Whether you are replacing the shaft in your own tractor or need to purchase one for a client, there are several factors to consider. The right PTO shaft for your tractor should be compatible with the equipment you currently use. For instance, a shaft that can be used in a farm tractor will fit a different farm tractor than one used in a construction machine.

First of all, a safety shield is a critical part of your IID shaft. The shielding will help keep the entire shaft free of any potential hazards. Typically, shielding will cover the straight part of the shaft, universal joints, and PTO connection. A shield can also help protect you from injury if you accidentally run into the shaft or touch the guard.

A power take off shaft will be the best choice if you are using a tractor for other applications, such as mowing, shredding, or plowing. A PTO shaft is also a crucial part if you own a large tractor or implement. It will allow you to operate your equipment with maximum efficiency.

An IID shaft is designed to slide into another piece when the tractor’s PTO is engaged. A disconnected IID shaft can pull the two pieces apart and cause the tractor to swing uncontrollably when it is engaged. This can cause serious injuries or even death. You should not engage a PTO if you aren’t certain of its strength.

To ensure the safety of the driveline shield, check for proper alignment of the PTO shaft. If it isn’t aligned properly, foreign materials can enter the shaft bearings. A damaged driveline shield can also lead to driveline separation, particularly when the tractor is making sharp turns or downhills. In addition, improper alignment of the drawbar may damage the protective shield that protects the shaft.

Choosing the right PTO series size requires proper measuring of each part. Measure the length of each yoke outside the PTO shaft and determine the appropriate PTO series size. The PTO yoke size chart can be helpful when choosing the correct size for your tractor.

Reverse PTO

Many different applications call for a reverse PTO shaft. These adapters allow the PTO shaft to be turned in the opposite direction of the engine, matching the rotation of the power take-off to the rotation of the equipment it drives. They can be used to space the power take-off away from the transmission case and improve clearance for a direct-coupled pump or driveshaft.

Reverse PTO shafts are available for CZPT . They are designed for six-spline 540-rpm applications. They also offer the option of multi-speed operation. Reversed PTOs are a great option for implements that can get stuck.

Reverse PTOs can be used on most types of PTO. The reverse version has a gearbox that allows it to rotate backward. These are ideal for implements that can get stuck in a field. A reverse PTO shaft makes it possible to work with the implement without having to wait for it to get unstuck.

When using a PTO, it’s important to know which type of gearbox is needed. If you have an older model, you’ll probably need a reverse PTO shaft. These are generally used on older, vintage tractors with ground drive PTO. The ground speed pTO shafts match the speed of the tractor’s final drive, so when the tractor is in reverse, the gearbox will turn backward. This feature will not function if you’re working stationary, though.

A tractor with a reverse PTO is important for a number of reasons. For example, the reverse PTO can help you turn a stuck tractor in the opposite direction, which is useful when a piece of farm equipment becomes stuck in mud or when you need to push a stuck implement back. In addition, it allows you to use the tractor’s power to operate various implements. The reverse PTO also helps you know how much power is needed to run various implements on various terrain.

In addition to being convenient, reverse PTO shafts also help reduce the risk of damage to implements attached to the PTO. It’s vital to keep a PTO shaft in good working order.

Square rigid shaft

When you are looking for a new square rigid PTO shaft, you should consider a few factors. Choosing the right one can be a challenge, as the process is not always simple. For instance, there are a lot of choices when it comes to different brands and interpretations. You can even choose to purchase a square rigid shaft that is not square.

Torsional rigidity is a measure of the ability of a shaft to resist torsional forces. The higher the value of J, the more rigid the shaft will be. For example, a steel shaft has a higher torsional rigidity than an HDPE shaft. The correct value of J can have a big impact on the design decisions.

Another factor to consider is the type of shaft coupling. Rigid shaft couplings are best for shafts that are perfectly aligned. While flexible couplings are flexible enough to accommodate small misalignments, they are not as flexible as the flexible ones. Rigid shaft couplings, which are typically made of metal, are not designed for high-speed rotation.

Rigid couplings are a good choice for a wide range of applications. Rigid couplings are available in many sizes and configurations, and can be used with either a powered or an unsupported shaft. Rigid couplings are also available with keyways to transmit torque.

Torsional rigidity depends on the geometry of the components. A higher torsional rigidity means a shaft is more resilient to twisting. However, excessive twisting can result in unstable performance. As a result, it is important to avoid over-twisting a shaft.

Flange couplings are another option. These couplings have two flanges that are attached to each other with bolts or nuts. They are very similar to split muff couplings and sleeve couplings. The difference is that flange couplings have two flanges – one for the shaft and one for the coupling hub.

If you are thinking about purchasing a square rigid PTO shaft for your tractor, be sure to consider the features that will best serve your specific needs. While you may be considering the price of this new shaft, remember that it is a machine part that could be dangerous.

Economy PTO

There are several standard types of PTO shafts. They can vary in diameter and number of splines, and are designed to work with a specific speed range. The following are the main differences between these types. Choosing the right type for your application will depend on its application. One of the most important considerations to make when choosing a PTO shaft is the ratio between the shaft’s diameter and the toothed wheels that are attached to it.

When choosing a PTO shaft, consider the amount of torque you need. In general, an economy PTO shaft should be able to support a maximum load of 540 Nm. In addition, it should be able to handle a high-speed output. An economy PTO shaft may need less torque than a high-performance model.

Economy PTO shafts come in two basic styles: North American and Italian. These two types are designed to provide constant-speed output and balance the power input of a tractor. There are also various other styles of PTO shafts available, including square and rectangular half-shaft assemblies. You can also purchase extra parts to repair a worn PTO shaft.

The control/monitoring unit in a PTO includes a screen display and a manual control for selecting engaged or disengaged PTO states. In addition, there is a switch in the cab mounted control unit 14 that selects normal and economy modes when driving the PTO. These modes utilize different gears to achieve the desired PTO shaft revs.

To select the right PTO speed, select the lever in economy mode and increase the throttle to the appropriate rpm. The PTO speed should be 540 RPM. The control/monitoring unit 14 will use this information to adjust the clutch control parameters. In addition to the PTO speed, it will also display the torque on the PTO shaft.

Economy PTO shafts are ideal for a variety of applications. These PTOs allow the tractor to run at lower rpms, thereby reducing noise and vibrations. They are typically available in both hydraulic and mechanical types.

editor by CX 2023-05-04

China steel seamless triangular pipe q345b st52 for pto drive shaft triangle pto shaft carrier bearing

Application: Fluid Pipe, Boiler Pipe, Drill Pipe, Hydraulic Pipe, Fuel Pipe, OIL PIPE, Chemical Fertilizer Pipe, Structure Pipe, Other

Alloy Or Not: Is Alloy

Area Condition: triangle

Specific Pipe: API Pipe

Thickness: 1.5 – thirty mm

Standard: JIS

Size: 12M, 5.8-12m

Certification: API

Grade: 16MN Q345B

Surface area Therapy: as consumer request

Tolerance: ±15%, ±20%, +-.1MM

Processing Services: Welding, Punching

Oiled or Non-oiled: Slightly Oiled

Invoicing: by genuine excess weight

Shipping Time: 22-30 times

Item title: Higher precision cold rolled seamless Alloy Steel Tube

Engineering: Cold Rolled Cold Drawn

Area: Vibrant

Content: ten#.twenty#.forty five#.16mn,20Cr,40Cr, 35CrMo,STKM13A

Shape: triangle

Usage: pto push shaft

Packing: Bundles

Payment conditions: T/T T/C

MOQ: 10 Ton

Packaging Specifics: Regular Exporting Seaworthy Packing

Port: HangZhou port ,ZheJiang port

| Item Title | special condition seamless metal pipe |

| condition | Triangular |

| Content | 10#,20#,45#,Q345,A106-B,20Cr,40Cr,42CrMo,St37,St52,ASTM 4140 and many others.16Mn, Q235,Q195, |

| Normal | JIS,GB,ASTM,DIN |

| Technique | Cold Rolled |

| Duration | five.8m~12m/tailored design and style |

| Surface Treatment method | black portray, varnish, oil, galvanized, anti corrosion coatings |

| Packaging | one. Bundle packing.2. Bevelled end or basic conclude or warnished as for each buyer’s needed.3. Marking: as for each customer’s requests. |

| MOQ | 10 ton for normal substance |

| Payment Phrases | T/T,L/C and many others |

| Benefits | one.Reasonable price with exceptional quality2.Abundant stock and prompt delivery3.Abundant provide and export encounter, sincere service4.Reliable forwarder, 2-hour absent from port. |

Packing Packing Specifics : Bundles with steel straip or Picket box ,as customers’ request

1. Bare Bundles 2. Bundles with metal straip and woven bag 3. Wood box Supply&Exporting Normal Exporting Seaworthy Packing1. 20ft container: 26tons (Can load 5.8M Max)2. 40ft container: 26tons (Can load 12M Max)3. by bulk vessel or as your needs

Exporting to All in excess of the worldOur metal pipes exported to several countries Germany, South Korea, Russia, the Philippines,India, Egypt, the United Kingdom and so on,acquire the believe in of customers.

Make contact with me Associated Merchandise

drive shaft yoke

editor by czh

Best price made in China – replacement parts – PTO shaft manufacturer & factory St1538, triangular pto shaft tubing St1540, St1638, St1640, Gun45 Universal Joints with ce certificate top quality low price

We – EPG Group the largest agricultural gearbox and pto factory in China with 5 diverse branches. For more details: Cell/whatsapp/telegram/Kakao us at: 0086-13083988828

new holland 489 haybine pto shaft Our employed push shaft around me items a thousand pto to 540 pto adapter is ford figo push shaft cost well-liked one thousand pto shaft sizes exported comer industries pto guard to pto slip clutch tractor offer the pto protect components United fifty inch driveshaft States, spicer driveshaft Germany, Australia, Russia, Spain, Hungary, Zimbabwe, Ukraine, Nigeria, Peru, Brazil, Center and South America, Thailand, Pakistan, Indonesia, a lot more than sixty nations around the world and regions. EPG Equipment is positioned in XiHu Area HangZhou Zhejiang ,China. It is 30km from our manufacturing facility to HangZhou global airport. Our company create variation sort of Staked Universal Joint, you should feel totally free to make contact with us, we can supply any Staked u-jointa in accordance to your sample or drawings.

| D | L | Sort |

| 15 | 38 | st1538 |

| fifteen | 40 | st1540 |

| 16 | 38 | st1638 |

| 16 | forty | st1640 |

| twenty | fifty two | GUN45 |

| 22 | fifty seven | gut24 |

| 24 | fifty six.5 | UJ2456SD |

| 24 | 62,five | gu200sd |

| 24 | seventy four,5 | u728/4 |

| 24 | 88 | G9M012BTA |

| 27 | seventy two | UJ2772SD |

| 27 | 75 | G9M013 BTA |

| 27 | 80 | U178 |

| 27 | 88 | G9M038 BTA |

| thirty | ninety two | cc562 |

| 31 | 88 | G9M040BTA |

Best factory made in China – replacement parts – PTO shaft manufacturer & factory High replacement pto shaft Durable Universal Triangular Tube Yoke for Agricultural Transmission Machine with ce certificate top quality low price

We – EPG Team the largest agricultural gearbox and pto factory in China with 5 distinct branches. For more specifics: Cell/whatsapp/telegram/Kakao us at: 0086-13083988828

pto shaft on tractor EPG tsc pto shaft go over Machinery bush hog drive shaft is 1 inch square pto shaft located king kutter travel shaft areas in 2014 mustang gt driveshaft XiHu agri offer pto shaft Region pto shaft for john deere brush hog HangZhou split travel shaft Zhejiang silverado efficiency driveshaft ,China. It is 30km from our factory to HangZhou intercontinental airport. Major merchandise incorporate: manure spreading truck, potato planting/harvesting device, disc plough, disc harrow, grass Mower/slasher, corn and wheat thershers, seeder, mouldboard plow, deep subsoiler devices, rotary tiller, rear blade, fertilizer spreader, blend rice harvester, corn thresher, farm trailer, ridger, trencher, stubble cleaner, earth auger, cultivator and its add-ons: Plow disc blades, harrowing movie, plough tip and share, cultivator tine, casting areas and many others.

High resilient universal triangular tube yoke for Agricultural Transmission Machine

1. Tubes or Pipes

We have presently got Triangular profile tube and Lemon profile tube for all the series we offer.

And we have some star tube, splined tube and other profile tubes necessary by our buyers (for a certain collection). (Remember to recognize that our catalog doesnt have all the products we make)

If you w EPT tubes other than triangular or lemon, make sure you offer drawings or pictures.

2.Finish yokes

We have acquired numerous types of swift release yokes and basic bore yoke. I will recommend the normal type for your reference.

You can also ship drawings or pictures to us if you are not able to uncover your item in our catalog.

3. Security devices or clutches

I will connect the detai EPT of security units for your reference. We have previously have Free wheel (RA), Ratchet torque limiter(SA), Shear bolt torque limiter(SB), 3types of friction torque limiter (FF,FFS,FCS) and overrunning couplers(adapters) (FAS).

four.For any other much more EPT specifications with plastic guard, relationship strategy, color of painting, package deal, and so forth., you should feel free to allow me know.

Functions:

1. We have been specialised in designing, producing drive shaft, steering coupler shaft, universal joints, which have exported to the Usa, Europe, Australia and many others for years

two. Application to all sorts of basic mechanical situation

3. Our merchandise are of higher depth and rigidity.

four. Heat resist EPT & Acid resistant

five. OEM orders are welcomed

Our manufacturing unit is a major company of PTO shaft yoke and universal joint.

We manufacture large quality PTO yokes for different autos, EPT machinery and gear. All items are built with rotating lighter.

We are currently exporting our products all through the entire world, specially to North The usa, South The us, Europe, and Russia. If you are intrigued in any merchandise, make sure you do not be reluctant to get in touch with us. We are hunting ahead to becoming your suppliers in the close to potential.

Best China manufacturer & factory Factory Made Standard Design Triangular Tube Magnetic Yoke For PTO Shaft With high quality best price

Due to our sincerity in offering best service to our clients, understanding of your needs and overriding sense of responsibility toward filling ordering requirements,a specialized supplier of a full range of chains, sprockets, gears, gear racks, V-belts, couplings and reducers, pto shaft, agricultural gearboxes….

Overview

Quick Details

- Warranty:

-

1.5 years

- Applicable Industries:

-

AT series with tri-lobe tube (triangular) The triangular tube shape is the most used, from lightweight to fairly heavy applications. In the case of applications with high sliding, the R version with Rilsan coating is also available. AL series with two-lobe tubes (lemon).

Manufacturing Plant

- After Warranty Service:

-

Online support

- Local Service Location:

-

none, Italy

A novel design that uses a simple coil spring mounted in the breather’s air passageway solves the problem. The interior of the spring does not provide a continuous surface where bubbles can form, and this eliminates the percolating effect and resulting oil transfer.

- Showroom Location:

-

ITALY

- Place of Origin:Zhejiang, China

- Brand Name:

-

OEM

- certificate:

-

CE

- Material:

-

Metal

- Processing of yoke:

-

Forging

- Design:

-

Customized

- Certificate:

-

CE Certificate

Supply Ability

- Supply Ability:

- 80000 Piece/Pieces per Month

Packaging & Delivery

- Packaging Details

- Standard export packing

- Port

- NINGBO OR SHANGHAI

Online Customization

Main products include: manure spreading truck, potato planting/harvesting machine, disc plough, disc harrow, grass Mower/slasher, corn and wheat thershers, seeder, mouldboard plow, deep subsoiler machines, rotary tiller, rear blade, fertilizer spreader, combine rice harvester, corn thresher, farm trailer, ridger, trencher, stubble cleaner, earth auger, cultivator and its accessories: Plow disc blades, harrowing film, plough tip and share, cultivator tine, casting parts etc.

Product Information

Product Information

PTO Shaft

The power take-off (PTO) is a sophisticated mechanism, allowing implements to draw energy from the engine and transmit it to another application. It works as a mechanical gearbox which can be mounted on the vehicle’s transmission.

The power take-off shaft (PTO shaft) is a critical component, designed and manufactured for continuous heavy-duty use. A good PTO shaft should be strong enough to bear the torsion and shear stress and minimize vibration.

Setforge, the forging subsidiary of Ever-Power Group, manufactures cold extruded PTO shafts for all types of agriculture vehicles. Our PTO shafts offer great dependability and durability during daily use.

EP Group has been internationally recognized as a reliable global supplier. Our state-of-the-art manufacturing process and experienced engineers ensure the top-quality of all Farinia components.

| After Warranty Service | Video technical support |

| Applicable Industries | Manufacturing Plant |

| Local Service Location | Italy |

| Showroom Location | Italy |

| Warranty | 1.5 years |

| Place of Origin | China |

| China | Zhejiang |

| Brand Name | EPG |

| certificate | CE |

| Material | Metal |

| Processing of yoke | Forging |

| Design | Customized |

| Certificate | CE Certificate |

Product Display

Product Display

PTO Drive Line Gen …

HP21 Skid Steer Au …

Tie Rod Cylinder H …

CompanyInfo

Company Profile

Ever-Power Group

EPG have high-tech machinery and test equipment. We can produce world class high precision products.

Certifications

Certifications

Shipment & Payment

Our Advantages

A: Your inquiry related to our products or prices will be replied in 24 hours.

B: Protection of your sales area, ideas of design and all your private information.

C: Best quality and competitive price.

……

faq

FAQ

1) How can I place order?

A: You can contact us by email about your order details, or place order on line.

2) How can I pay you?

A: After you confirm our PI, we will request you to pay. T/T (HSBC bank) and Paypal, Western Union are the most usual ways we are using.

……