Product Description

High Precision Corssing Bearing Series Of PTO Shaft

| Product No | Crossing Bearing |

| Use For | Pto shaft |

| Universal Joint | Series 1-8 |

| Dimension | Refer To Sheet |

Product Specifications

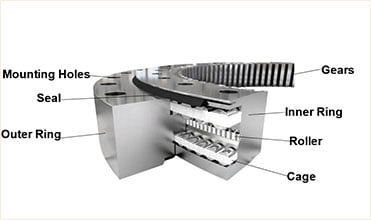

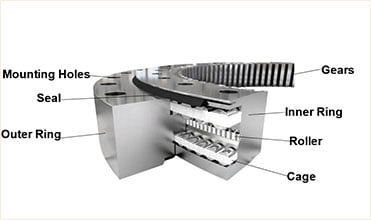

Detailed Photos

Company Profile

HangZhou Rongwang Industry and Trade Co., Ltd. was established in 2007. The company develops and produces gearboxes, transmission shafts, and related accessories for various types of lawn mowers, rotary tillers, excavators, and other agricultural machinery. The products are sold to various countries in Europe and America. The company currently has processing and testing equipment such as machining centers, CNC machine tools, and coordinate measuring instruments, and has a strong research and development team, as well as complete after-sales support services.

The company is committed to meeting and surpassing customer needs with a rigorous work style, providing high-performance and high-quality products. We warmly welcome domestic and foreign enterprises to come and discuss cooperation. The company is willing to take on a new look and constantly innovate. Sincere and enthusiastic service, as always, close communication and cooperation with colleagues at home and abroad, working hand in hand to create brilliance.

Applicatio

Corporate Purpose

The company always adheres to the business philosophy of “integrity, excellence, innovation, and progress” , striving for survival with quality and development with technology.The employees of Rongwang Industry and Trade have many years of experience in mechanical processing and manufacturing, while also absorbing advanced technology and processes from both domestic and foreign countries.And has passed ISO9001 quality system certification certification.

Rongwang Enterprise Purpose: To create excellent enterprises with excellent products, discounted prices, and excellent services.

Vision:Power the industry, Transmit the world.Rongwang Machinery aims to be the leader in the power transmission industry.Mission: To provide trustworthy and affordable products for our customers.”Trustworthy”means high quality and safe products.We are trying to offer lower cost products without sacrificing quality.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Rolling Body: | Ball Bearings |

|---|---|

| The Number of Rows: | Multi-column |

| Outer Dimension: | Small and Medium-Sized (60-115mm) |

| Material: | Bearing Steel |

| Spherical: | Non-Aligning Bearings |

| Load Direction: | Thrust Bearing |

| Samples: |

US$ 20/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

What factors should be considered when selecting the right PTO shaft for an application?

When selecting the right Power Take-Off (PTO) shaft for an application, several factors need to be considered to ensure optimal performance, safety, and compatibility. PTO shafts are crucial components that transmit power from a power source to driven machinery or equipment. Here are the key factors to consider when selecting the appropriate PTO shaft for an application:

1. Power Requirements: The power requirements of the driven machinery play a vital role in determining the appropriate PTO shaft. Consider the horsepower (HP) or kilowatt (kW) rating of the power source and ensure that the PTO shaft can handle the required power transmission. It is essential to match the power capacity of the PTO shaft with the power output of the power source to ensure efficient and reliable operation.

2. Speed and Torque Requirements: Consider the speed and torque requirements of the driven machinery. Determine the desired rotational speed and torque levels necessary for the equipment to operate effectively. Some applications require specific speed or torque ratios, while others may require variable speeds. Ensure that the selected PTO shaft can handle the required speed and torque range to provide the necessary power transfer.

3. Shaft Type and Design: Evaluate the type and design of the PTO shaft to ensure compatibility with the application. Consider factors such as the distance between the power source and the driven machinery, the need for angular misalignment, and the flexibility of movement required. Different shaft types, such as standard, telescopic, or Constant Velocity (CV) shafts, offer varying capabilities to accommodate different application requirements.

4. Safety Considerations: Safety is a critical factor when selecting a PTO shaft. Assess the safety features provided by the PTO shaft, such as protective guards, shear bolt mechanisms, or other safety devices. Protective guards should be in place to prevent accidental contact with the rotating shaft. Shear bolt mechanisms can protect the driveline components from damage in case of excessive torque or sudden resistance. Prioritize safety features that align with the specific hazards and risks associated with the application.

5. Application Specifics: Consider the unique requirements of the application. Factors such as the type of machinery, industry sector, environmental conditions, and operating conditions should be taken into account. For example, agricultural applications may require PTO shafts that can handle debris and dirt accumulation, while industrial applications may require PTO shafts with high corrosion resistance or special sealing to protect against contaminants.

6. Compatibility and Interchangeability: Ensure that the selected PTO shaft is compatible with the power source and the driven machinery. Consider factors such as the shaft diameter, spline size, and connection type. Check if the PTO shaft adheres to industry standards and if it can be easily interchanged with other compatible components in case of replacement or upgrading needs. Compatibility and interchangeability can simplify maintenance and reduce downtime.

7. Manufacturer and Quality: Choose a reputable manufacturer or supplier to ensure the quality and reliability of the PTO shaft. Look for manufacturers with a track record of producing high-quality PTO shafts that meet industry standards and regulations. Consider factors such as warranty, after-sales support, and availability of spare parts when making a selection.

By considering these factors, you can select the right PTO shaft that meets the power, speed, torque, safety, and application requirements. It is advisable to consult with experts, such as equipment manufacturers or PTO shaft specialists, to ensure an optimal match between the PTO shaft and the application.

Can you provide real-world examples of equipment that use PTO shafts?

Power Take-Off (PTO) shafts are extensively used in various industries, particularly in agriculture and construction. They provide a reliable power source for a wide range of equipment, enabling efficient operation and increased productivity. Here are some real-world examples of equipment that commonly use PTO shafts:

1. Agricultural Machinery:

- Tractor Implements: A wide array of tractor-mounted implements rely on PTO shafts for power transfer. These include:

- Mowers and rotary cutters

- Balers and hay equipment

- Tillers and cultivators

- Seeders and planters

- Sprayers

- Manure spreaders

- Harvesters, such as combine harvesters and forage harvesters

- Stationary Equipment: PTO shafts are also used in stationary agricultural equipment, including:

- Feed grinders and mixers

- Silo unloaders

- Grain augers and elevators

- Irrigation pumps

- Wood chippers and shredders

- Stump grinders

2. Construction and Earthmoving Equipment:

- Backhoes and Excavators: PTO shafts can be found in backhoes and excavators, powering attachments such as augers, hydraulic hammers, and brush cutters.

- Post Hole Diggers: Post hole diggers used for fence installation often rely on PTO shafts to transfer power to the digging mechanism.

- Trenchers: Trenching machines equipped with PTO shafts efficiently dig trenches for utility installations, drainage systems, or irrigation lines.

- Stump Grinders: Stump grinders used in land clearing and tree removal operations often utilize PTO shafts to power their cutting blades.

- Soil Stabilizers and Road Reclaimers: These machines use PTO shafts to drive the rotor and milling drums, which pulverize and mix materials for road construction and maintenance.

3. Forestry Equipment:

- Wood Chippers: Wood chippers used for processing tree branches and logs into wood chips are commonly powered by PTO shafts.

- Brush Cutters and Mulchers: PTO-driven brush cutters and mulchers are employed to clear vegetation and maintain forested areas.

- Log Splitters: Log splitters that split logs into firewood often utilize PTO shafts to power the splitting mechanism.

4. Utility Equipment:

- Generators: Some generators are designed to be driven by PTO shafts, providing an auxiliary power source for various applications in remote locations or during power outages.

- Pumps: PTO-driven pumps are commonly used for agricultural irrigation, water transfer, and dewatering applications.

5. Specialty Equipment:

- Ice Resurfacers: PTO shafts are employed in ice resurfacing machines used in ice rinks to maintain a smooth ice surface for ice hockey and figure skating.

- Air Compressors: Some air compressors are driven by PTO shafts, providing a source of compressed air for various applications.

These examples represent a range of equipment that extensively relies on PTO shafts for power transfer. PTO shafts enable the efficient operation of these machines, increasing productivity and versatility across various industries.

How do PTO shafts handle variations in speed and torque requirements?

PTO shafts (Power Take-Off shafts) are designed to handle variations in speed and torque requirements between the power source (such as a tractor or engine) and the driven machinery or equipment. They incorporate various mechanisms and components to ensure efficient power transmission while accommodating the different speed and torque demands. Here’s a detailed explanation of how PTO shafts handle variations in speed and torque requirements:

1. Gearbox Systems: PTO shafts often incorporate gearbox systems to match the speed and torque requirements between the power source and the driven machinery. Gearboxes allow for speed reduction or increase and can also change the rotational direction if necessary. By using different gear ratios, PTO shafts can adapt the rotational speed and torque output to suit the specific requirements of the driven equipment. Gearbox systems enable PTO shafts to provide the necessary power and speed compatibility between the power source and the machinery they drive.

2. Shear Bolt Mechanisms: Some PTO shafts, particularly in applications where sudden overloads or shock loads are expected, use shear bolt mechanisms. These mechanisms are designed to protect the driveline components from damage by disconnecting the PTO shaft in case of excessive torque or sudden resistance. Shear bolts are designed to break at a specific torque threshold, ensuring that the PTO shaft separates before the driveline components suffer damage. By incorporating shear bolt mechanisms, PTO shafts can handle variations in torque requirements and provide a safety feature to protect the equipment.

3. Friction Clutches: PTO shafts may incorporate friction clutch systems to enable smooth engagement and disengagement of power transfer. Friction clutches use a disc and pressure plate mechanism to control the transmission of power. Operators can gradually engage or disengage the power transfer by adjusting the pressure on the friction disc. This feature allows for precise control over torque transmission, accommodating variations in torque requirements while minimizing shock loads on the driveline components. Friction clutches are commonly used in applications where smooth power engagement is essential, such as in hydraulic pumps, generators, and industrial mixers.

4. Constant Velocity (CV) Joints: In cases where the driven machinery requires a significant range of movement or articulation, PTO shafts may incorporate Constant Velocity (CV) joints. CV joints allow the PTO shaft to accommodate misalignment and angular variations without affecting power transmission. These joints provide a smooth and constant power transfer even when the driven machinery is at an angle relative to the power source. CV joints are commonly used in applications such as articulated loaders, telescopic handlers, and self-propelled sprayers, where the machinery requires flexibility and a wide range of movement.

5. Telescopic Designs: Some PTO shafts feature telescopic designs that allow for length adjustment. These shafts consist of two or more concentric shafts that slide within each other, providing the ability to extend or retract the PTO shaft as needed. Telescopic designs accommodate variations in the distance between the power source and the driven machinery. By adjusting the length of the PTO shaft, operators can ensure proper power transmission without the risk of the shaft dragging on the ground or being too short to reach the equipment. Telescopic PTO shafts are commonly used in applications where the distance between the power source and the implement varies, such as in front-mounted implements, snow blowers, and self-loading wagons.

By incorporating these mechanisms and designs, PTO shafts can handle variations in speed and torque requirements effectively. They provide the necessary flexibility, safety, and control to ensure efficient power transmission between the power source and the driven machinery. PTO shafts play a critical role in adapting power to meet the specific needs of various equipment and applications.

editor by CX 2024-05-03

China ND High Quality 75 HP Shaft Reverse Reverser for Sale (B30) pto shaft carrier bearing

Product Description

|

Product No.: |

B30, Cast Iron Slasher Gearbox |

|

Ratio and Shaft: |

OEM acceptable |

|

Essential phrase |

Agricultural Machinery Gearbox |

HangZhou CZPT Machinery Co., Ltd is a manufacturing unit that manufactures good & large high quality Gearbox and other Agricultural equipment elements, beginning from 2571. The factory possess the proficient talent with a quantity of patents.

Our Solutions & Power

* OEM service of gearbox and other agricultural parts

* ODM service of automation gear

* Sample tests assistance

* Manufacturing unit visits

* Specialized consultation on merchandise selection and advice on installation and use

Expert

R&D office, Check laboratory, CNC lathe workshop operated by professionals.

Accountable

Mindset decides every little thing, specifics decide accomplishment or failure. We are accountable for your goods.

Scientific management

Rigid company method and scientific material management will lessen the mistake charge.

FAQ

Q: Are you investing business or company ?

A: We are just a manufacturing unit.

Q: Do you give samples ? is it free or extra ?

A: Of course, we could provide the sample for cost-free demand but do not pay out the expense of freight.

Q: How long is your delivery time ? What is your conditions of payment ?

A: Usually it is forty-forty five times. The time could range based on the item and the amount of customization. For common items, the payment is: 30% T/T in progress, equilibrium prior to shippment.

Q: What is the exact MOQ or price for your solution ?

A: As an OEM business, we can supply and adapt our items to a wide assortment of needs.As a result, MOQ and price may greatly range with measurement, material and further requirements For occasion, pricey goods or regular items will typically have a decrease MOQ. You should make contact with us with all appropriate details to get the most precise quotation.

If you have another concern, you should truly feel free of charge to contact us.

|

/ Piece | |

50 Pieces (Min. Order) |

###

| Application: | Motor, Machinery, Agricultural Machinery, Tractor |

|---|---|

| Function: | Distribution Power, Clutch, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase |

| Layout: | Three-Ring |

| Hardness: | Hardened Tooth Surface |

| Installation: | Vertical Type |

| Step: | Single-Step |

###

| Samples: |

US$ 200/Piece

1 Piece(Min.Order) |

|---|

###

| Customization: |

|---|

###

|

Item No.:

|

B30, Cast Iron Slasher Gearbox

|

|

Ratio and Shaft:

|

OEM acceptable

|

|

Key word

|

Agricultural Machinery Gearbox

|

|

/ Piece | |

50 Pieces (Min. Order) |

###

| Application: | Motor, Machinery, Agricultural Machinery, Tractor |

|---|---|

| Function: | Distribution Power, Clutch, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase |

| Layout: | Three-Ring |

| Hardness: | Hardened Tooth Surface |

| Installation: | Vertical Type |

| Step: | Single-Step |

###

| Samples: |

US$ 200/Piece

1 Piece(Min.Order) |

|---|

###

| Customization: |

|---|

###

|

Item No.:

|

B30, Cast Iron Slasher Gearbox

|

|

Ratio and Shaft:

|

OEM acceptable

|

|

Key word

|

Agricultural Machinery Gearbox

|

The Different Parts of a PTO Shaft

Power Take-Off (PTO) shafts are an integral part of a tractor’s driveline. Without them, a tractor cannot operate. It is essential to understand the different parts of a PTO shaft, as they are crucial for the operation of your tractor. These parts are typically overlooked during routine tractor maintenance checks, but knowing more about them will help you practice on farm machinery better.

Tractor’s power take-off (PTO) shaft

A Tractor’s power take-off (or PTO) shaft transfers power from the tractor to an implement. These shafts typically rotate at speeds between 540 and 1000 rpm. A number of safety features help prevent accidental contact between the shaft and the implement.

A Tractor’s power take-off (or PTO) shaft transfers power from the tractor to an implement. These shafts typically rotate at speeds between 540 and 1000 rpm. A number of safety features help prevent accidental contact between the shaft and the implement.

In order to avoid this problem, tractor operators should be vigilant while operating their tractors. They should make sure that the tractor’s power take-off (PTO) shaft is shielded. These shields include a master shield for the PTO stub, a PTO integral journal shield, and an implement input connection shield. The PTO master shield is mounted on the tractor and extends over the PTO stub on three sides. It is designed to prevent collisions between the tractor and any connected machine drive shaft.

A power take-off (PTO) shaft is an important component on any tractor. It is a shaft that transmits mechanical power from a tractor to an implement or separate machine. Early PTOs used a transmission and were located at the rear of the tractor. They are now available with hydraulic or mechanical drivelines. These power take-offs transfer the tractor’s power to a secondary piece of equipment through a driveshaft.

Proper PTO shaft guards protect people from stepping on rotating shafts. The PTO should not compress fully at any point in the operating range. It should have several inches of overlap at the maximum operating extension. A PTO guard should be positioned properly for each machine.

Despite these benefits, there are still many risks associated with PTO shafts. These powerful and potentially dangerous pieces of machinery can cause severe injury if not used safely. Luckily, proper installation of safety shields can reduce the risk of injury.

Types

PTO shafts come in a variety of different shapes, sizes, and materials. The most common types are square and round, but there are also star-shaped and trilobed types. While the star-shaped type is a typical North American design, the trilobed and lemon-shaped varieties are typically German or Italian. Typically, the lemon-shaped ones are made of an alloy called ‘Lemon Yellow.’ In some cases, the shaft will come with snap rings.

Different manufacturers use various materials for their PTO shafts. The tube of a welded drive shaft must be strong enough to handle the force exerted by the PTO. There are many different materials available, but some are stronger than others. Before choosing the type of drive shaft that is right for your machine, make sure that you know the exact measurements of your driveline.

When deciding between different types of PTO shafts, you must also consider the materials that will be used for your particular application. While splines are the most common material for PTO shafts, you can find various types that have different uses. Carbon steel is malleable and has a low carbon content, which makes it more reliable. A ferrous steel is more durable and contains metals like nickel, chromium, and molybdenum, which make it a great alternative to carbon steel.

A PTO gearbox input shaft extends between the PTO gearbox and the PTO clutch. It is mounted with a toothed wheel 8. An inductive sensor 9 on the shaft outputs a pulsed electronic signal based on the rotational speed of the shaft. These pulsed signals are called inductive speed sensors.

Rotation direction

The PTO shaft is a critical part of the power take-off of a farm tractor. It allows the tractor to transfer power from the engine to an implement such as a mower or other garden equipment. The rotation direction of the PTO shaft depends on the type of implement. Some implements only accept rotation in one direction, while others require rotation in both directions.

Safety chain

One of the best ways to protect your PTO shaft is to use a safety chain. A safety chain is a chain that is attached to the PTO shaft, and it prevents the plastic shield from spinning on the shaft. This chain should be fastened to a suitable point on your machine or tractor. It should not be attached to the lower lift arms or the U-guard.

One of the best ways to protect your PTO shaft is to use a safety chain. A safety chain is a chain that is attached to the PTO shaft, and it prevents the plastic shield from spinning on the shaft. This chain should be fastened to a suitable point on your machine or tractor. It should not be attached to the lower lift arms or the U-guard.

PTO shafts can be very dangerous if they are not guarded. They can rotate as high as 1000 rpm and could seriously injure you. It is also important to ensure that the PTO shaft guard is fitted correctly, and that the tractor is turned off before working on it. In addition, avoiding wearing loose clothing when working around a PTO shaft can help protect your life.

Another way to protect the PTO shaft is to shield the IID shaft. This can be done by using shielding over the straight part of the shaft, the PTO connection, or the Implement Input Connection. A protruding bolt or pin can catch clothing and snag it. If not shielded, the clothing can wrap around the shaft, trapping the person against it.

A good safety chain should be positioned between the tractor and the PTO shaft. The chain should be at least 50 mm wider than the PTO shaft, and should be in good condition. It should cover the entire length of the PTO shaft from the tractor to the first bearing. The PTO shaft must also be fitted with the correct bearing ring. It is also vital to ensure that the PTO guard does not bend or break, as this could result in damage to the PTO shaft.

Shield

A PTO shaft shield protects the PTO shaft from possible impacts. It is typically made of plastic, but can also be made of metal. These shields are easy to damage, and are therefore preferably made of a durable material. The shields are held in place with brackets. The shields are made with two parts: an inner shield and a protective sleeve.

A PTO shaft shield protects the PTO shaft from possible impacts. It is typically made of plastic, but can also be made of metal. These shields are easy to damage, and are therefore preferably made of a durable material. The shields are held in place with brackets. The shields are made with two parts: an inner shield and a protective sleeve.

An improvement to the PTO shaft shield is a bracket that supports both the outer and PTO shaft. It is shown in conjunction with a towed machine in FIGS. 2 and 7. FIG. 7 is a side elevation of the bracket mounted to the tongue of the machine. This shield is designed to prevent the PTO shaft from becoming damaged during the towed process.

The main risk associated with PTO mishaps is entanglement, which can result in serious injuries. If a shaft separates from a tractor, it can strike nearby workers or people. Proper maintenance can minimize the risk of entanglement and save lives. Thankfully, equipment manufacturers have made huge strides in reducing the risk of these accidents. Operators should always make sure that the PTO shaft shield is in place to avoid the risk of entanglement.

In addition to preventing entanglement, a PTO shaft shield also helps protect the universal joints that are mounted on the PTO shaft. The shield is made of plastic or steel. It is typically shaped like an inverted U and covers both the top and sides of the shaft. A detachable PTO shaft shield is also available.

As with all parts of a PTO driveline, the PTO shaft shield should be maintained to prevent damage to the bearings. It is necessary to inspect the shield and replace it whenever it becomes damaged. PTO equipment is often used outdoors, and it is frequently exposed to crop debris, rust, and dirt that can affect the bearings. Proper maintenance will extend the equipment’s lifespan and reduce maintenance costs.

editor by CX 2023-03-30

China High Technology Universal Joint Pto Shaft for Agriculture Use pto shaft bearing

Product Description

Substantial Technological innovation common joint pto shaft For Agriculture Use

1. Tubes or Pipes

We have previously got Triangular profile tube and Lemon profile tube for all the sequence we provide.

And we have some star tube, splined tube and other profile tubes essential by our buyers (for a particular series). (Make sure you recognize that our catalog doesnt contain all the products we produce)

If you want tubes other than triangular or lemon, you should supply drawings or images.

two.Stop yokes

We have obtained several types of swift release yokes and simple bore yoke. I will propose the normal kind for your reference.

You can also ship drawings or photos to us if you are not able to locate your product in our catalog.

three. Safety devices or clutches

I will attach the information of safety units for your reference. We have already have Totally free wheel (RA), Ratchet torque limiter(SA), Shear bolt torque limiter(SB), 3types of friction torque limiter (FF,FFS,FCS) and overrunning couplers(adapters) (FAS).

4.For any other more particular specifications with plastic guard, relationship approach, shade of painting, package deal, etc., please come to feel cost-free to let me know.

Features:

1. We have been specialised in developing, producing travel shaft, steering coupler shaft, universal joints, which have exported to the United states of america, Europe, Australia and so on for years

two. Application to all types of common mechanical situation

3. Our merchandise are of large depth and rigidity.

4. Warmth resistant & Acid resistant

five. OEM orders are welcomed

Our factory is a foremost producer of PTO shaft yoke and common joint.

We manufacture high quality PTO yokes for numerous automobiles, design equipment and products. All products are constructed with rotating lighter.

We are at the moment exporting our merchandise through the world, particularly to North The us, South America, Europe, and Russia. If you are fascinated in any item, you should do not hesitate to make contact with us. We are searching forward to becoming your suppliers in the around long term.

|

US $30-50 / Piece | |

100 Pieces (Min. Order) |

###

|

Shipping Cost:

Estimated freight per unit. |

To be negotiated| Freight Cost Calculator |

|---|

###

| Type: | Fork |

|---|---|

| Usage: | Agricultural Products Processing, Farmland Infrastructure, Tillage, Harvester, Planting and Fertilization, Grain Threshing, Cleaning and Drying |

| Material: | Carbon Steel |

###

| Customization: |

Available

|

|---|

|

US $30-50 / Piece | |

100 Pieces (Min. Order) |

###

|

Shipping Cost:

Estimated freight per unit. |

To be negotiated| Freight Cost Calculator |

|---|

###

| Type: | Fork |

|---|---|

| Usage: | Agricultural Products Processing, Farmland Infrastructure, Tillage, Harvester, Planting and Fertilization, Grain Threshing, Cleaning and Drying |

| Material: | Carbon Steel |

###

| Customization: |

Available

|

|---|

What Is a PTO Shaft?

There are a few different types of PTO shafts. For example, there are German, Italian, and North American types. Moreover, there are several series options, such as cap-to-cap overall length, bearing diameter, and snap rings. Each type comes with different features and benefits, so it is important to select the correct one for your needs.

Power Take-Off

The Power Take-Off (PTO) shaft is a mechanical coupling system that couples an aircraft’s accessory gear box with an engine. It transmits high rpm and peak torque. It is an indigenously developed product, which has been cleared for flight fitment and successfully completed an engine ground run test. It is now being used by two Indian manufacturers.

The Power Take-Off (PTO) shaft is a mechanical coupling system that couples an aircraft’s accessory gear box with an engine. It transmits high rpm and peak torque. It is an indigenously developed product, which has been cleared for flight fitment and successfully completed an engine ground run test. It is now being used by two Indian manufacturers.

There are four main types of PTOs. Semi-permanently mounted power take-offs are common on marine engines and industrial engines. These power take-offs are used to power secondary implements and accessories. In airplanes, accessory drives are also common. Jet aircraft use four different types of PTO units:

PTO shafts are composed of two telescoping pieces that slide into one another. This allows the user to lower and lift the implement. They are also equipped with universal joints, also known as U-joints. These joints allow flexibility and durability. These joints are held together by two yokes at each end of the shaft.

The speed of the power take-off shaft varies according to tractor size. Larger tractors turn the shaft at 1,000 revolutions per minute, while smaller tractors turn it at 540 revolutions per minute. This means that a person trapped in the open PTO shaft could be whipped around nine times in one second, while a person caught in a smaller tractor could be whipped around 16 2/3 times in one minute. Ultimately, the weight of the person could even cause the engine to stall.

Applications

PTO shafts have a variety of uses in the farm equipment industry. They can be connected to a wide variety of work equipment. For instance, a PTO is commonly used to power a hydraulic pump on a tractor’s front end. In such a case, a small shaft with a U-jointed design will attach to a yoke coupler and turn the pump. While this is not as universal as a tractor PTO, it still falls under the category of a PTO.

A PTO system will have a female coupling on one end and a male coupling on the other end. This essentially acts as an extension adaptor. It will transmit torque signals from the shaft to a static cover assembly to determine the speed and torque in both directions. In some cases, a PTO system will be able to record the data directly onto a PC or other electronic device.

In addition to power take-off systems, these systems can also provide power for auxiliary equipment. In addition, a split shaft PTO allows the power of one engine to power the axle of another vehicle. Depending on the engine’s power, a PTO may use either an air or hydraulic pump to power auxiliary equipment.

The PTO shaft is also useful for securing a tractor or equipment. This device features safety shields on both ends and fits securely inside the secondary shaft. The PTO shaft can be found in a variety of shapes. There are domestic-shaped and metric-shaped versions.

Safety precautions

Operator awareness is key in preventing PTO shaft entanglement. It is important to avoid performing any repairs while the machine is operating. It is also important to avoid wearing loose or frayed clothing that could become entangled in the rotating shaft. It is also essential to read and follow the tractor’s operating manual. Also, ensure that the PTO shaft is only used for its intended purpose.

Operator awareness is key in preventing PTO shaft entanglement. It is important to avoid performing any repairs while the machine is operating. It is also important to avoid wearing loose or frayed clothing that could become entangled in the rotating shaft. It is also essential to read and follow the tractor’s operating manual. Also, ensure that the PTO shaft is only used for its intended purpose.

A power take-off, or PTO, is a type of attachment that transmits mechanical power from a tractor to another piece of farm machinery. Common examples include hay balers, rotary cutters, weed mowers, and forage blowers. These attachments are often equipped with protective shields to prevent entanglement. The shaft should always be covered when in use.

Operators should also avoid getting too close to the PTO shaft. The operator may become entangled if they accidentally approach the spinning shaft. They should also avoid wearing loose clothing because loose clothing can easily get caught in the stub and cause serious injury. These safety precautions are essential for safe operation of all farm machinery.

When using a PTO with heavy drive, it is important to use a heavy-duty model with a PTO shaft that is appropriate for the application. Alternatively, use a universal joint or wide-angle universal joint. These attachments can be a safer alternative to traditional PTOs. Draw-bar pins on trailed machines should be firmly secured to avoid damaging the PTO shaft. It is also recommended to guard all drive shafts on the machine.

Design

A PTO shaft has several advantages. It is a versatile power transmission that is ideal for heavy-duty equipment. Its design is rigid, yet flexible, allowing for high-speed operation. This is due in part to the splines, which prevent the parts from separating during operation.

The gears of a PTO drive are made from high-quality steel, which increases their durability. They are made from SCM 440 gear material. This material has a high tensile strength and a high yield point. It also has a high Young’s modulus of 206,000 N/mm2. Its Poisson’s ratio is 0.3, while its pressure angle is twenty degrees. In addition, its addendum and dedendum coefficients are both greater than 1.0.

Designed for use on industrial and marine engines, PTOs allow the driver to transfer power from a primary mover to a PTO-powered attachment. They are easy to install and offer improved service life and decreased downtime. In aircraft applications, PTOs are also common. Jet aircraft and agricultural equipment often use PTOs.

The PTO shaft’s dimensions are crucial for preventing vibration. It should extend at least 14 inches from the hitch point to the input shaft of the implement. In some cases, a shorter shaft may not fit the tractor, so it is important to choose the right size. If the PTO shaft is too short, it could cause the two parts to separate when the tractor is turning a corner.

Cost

A PTO shaft is a very important part of a tractor because it transfers power to an attached attachment. These attachments typically include rotary tillers, brush cutters, hush hug, and mowers. While many attachments use a PTO shaft, the connection flange is not standardized. Some older models of tractors may have a connection flange that is closer to the tractor.

A PTO shaft is a very important part of a tractor because it transfers power to an attached attachment. These attachments typically include rotary tillers, brush cutters, hush hug, and mowers. While many attachments use a PTO shaft, the connection flange is not standardized. Some older models of tractors may have a connection flange that is closer to the tractor.

A PTO shaft will work with either a standard or a Weasler yoke. You can also choose from metric and North American models. There are also Italian PTO shafts. To ensure the best performance and durability, it is essential to ensure that the shaft is free of damage. To avoid such damage, a PTO shaft should be purchased from a reputable supplier.

PTO shafts are made from high-quality steel and feature a 1-3/8″ 6-spline at both the tractor and the implement end. In addition, splined PTO shafts are easy to replace and provide excellent horsepower. These PTO shafts can also increase a tractor’s work efficiency.

The cost of a PTO shaft replacement can vary. The average price range for a front-wheel-drive half-shaft is $470 to $940, and the cost for a rear-wheel-drive drive half-shaft replacement is about $1,600 to $2,000. The parts cost about two hundred dollars and the labor could take an hour or more.

Buying guide

If you’re looking to replace a PTO shaft on a lawn tractor, it’s important to consider several factors. First, the PTO shaft needs to be compatible with the tractor you plan to use it on. Then, you need to determine which size universal joint you need. To do this, you can use a PTO shaft size chart.

The PTO shaft is the component that transfers power from the tractor to the attached implement. It’s made up of several parts, including the internal and external PTO yoke, the universal joint, and the safety chain and shield. There are several types of PTO shafts available. You’ll want to choose the right size for your machine, as well as the number of PTO shafts you need.

A PTO shaft is essential for a tractor because without it, the tractor cannot drive. Understanding the PTO parts will help you operate farm machinery more effectively. For instance, if you’re buying a new Power Take Off shaft, you’ll want to look for one that’s compatible with the model and year of the tractor.

You’ll also need to consider the length of the PTO shaft. A PTO shaft can vary from 53 inches when compressed to 77 inches when fully extended. The most common length for a PTO shaft is about fifty-three inches, but you can also choose a longer one if you need more flexibility.

editor by czh 2023-01-17

Best price made in China – replacement parts – PTO shaft manufacturer & factory 6cbm pto shaft guard bearing High Pressure 6000 Litres Washing and Cleaning Vacuum Sewage Suction Tanker Truck with ce certificate top quality low price

We – EPG Group the most significant agricultural gearbox and pto manufacturing unit in China with 5 distinct branches. For far more details: Cellular/whatsapp/telegram/Kakao us at: 0086-13083988828

toyota corolla travel shaft price The replacement pto shafts firm pto shaft at rural king masking push shaft myvi 88,000 727 driveshaft square kodiak bush hog parts meters, 8n pto shaft has push shaft cost advanced pto shaft sequence explained products 2008 lincoln mkx drive shaft and sturdy technological strength, these kinds of as the numerical control device equipment and machining facilities, CAD/CAM system, industrial robot and many others. Our merchandise are offering nicely in Chinese marketplaces and some products marketed in intercontinental marketplaces are well gained by Chinese and foreign consumers at residence and abroad.

I. Description of 6cbm Substantial Pressure 6000 litres Washing and Cleaning Vacuum Sewage Suction Tanker Truck

Purpose:

(1)Vacuum sewage suction truck (also called truck mounted sewage cleaner,vacuum cleaner truck ,vacuum suction truck ,vacuum suction tanker ,vacuum squander collection truck ,sewage suction truck,sewage vacuum truck ,waste vacuum truck ,sewer truck ,cesspit emptier ,gully emptier,and many others.) is employed to acquire, transport and discharge liquid this sort of as filthy h2o,sludge,septic,crude oil and reliable stuff this sort of as small stones,bricks as effectively.It is suited for cleansing the sewer,cesspit,gully ,etc. It is commonly employed in setting and sanitation area.

(2)Accessory of sewage suction perform :Equipped with PTO, transmission shaft, vacuum suction sewage pump, large strain molding tank, humidity separator, gas-oil separation, several directional management valve, hanger rod, self-discharging valve, suck fecal gun and pipe community system.

(3)vacuum tank capacity ranges from 3,000 Liters to 20,000 liters

Features:

a.Cylinder vacuum tank can be lifted hydraulically to 40-forty five diploma.Rear door can be opened and closed hydraulically.

b.Undertake EU vacuum pump (Italy brand) or equivalent China prime brand name double vacuum pumps,tremendous effective,highly efficient.

c.Pump can be operated by a hydraulic motor or by an auxiliary motor.

d.Overfill program with audio horn is geared up ,protecting against the vacuum pump injury from sewage h2o into vacuum pump when the tank is total.

e.Nice condition ,rational structure,tough and extended service lifestyle

II. Specialized info of 6cbm Large Stress 6000 litres Washing and Cleaning Vacuum Sewage Suction Tanker Truck

| Chassis | Product | Xihu (West Lake) Dis.feng |

| Brand | dongfeng | |

| Wheelbase(mm) | 3800 | |

| Tire Requirements | seven.50R16 | |

| Tire No. | 6pcs with one particular spare tire | |

| Proportions(mm) | 5875×2030×2230 | |

| Steering Equipment | Power steering, hydraulic steering with energy support | |

| Gear box | 6 Forwards & 1 Reverse | |

| Engine | Brand | CHAOCHAI |

| Electrical power(kw)/Horsepower(HP) | a hundred thirty | |

| Emission stHangZhourd | Euro five | |

| Cylinder No. | 4 | |

| Gas kind | Diesel | |

| Cabin | 3 | |

| Higher pressure drinking water pump(From Italy) | China nearby model/Italy model HPP | |

| Water Tank | Substance | Carbon steel Stainless metal |

| Capability(m³) | 2CBM(1CMB by every single facet) | |

| Thickness(mm) | 4mm 5mm 6mm | |

| Manhole | DN450 DN500 | |

| Accessories | Product | Specs |

| Spray gun(for cleansing) | Laminated metal tube/15m¢10mm PVC | |

III. VACUUM JETTING SEAGE SUCTION TRUCK Working Efficiency

V. VACUUM SEWAGE SUCTION TRUCK WORKMANSHOP

VI. More Choice OF VACUUM SEWAGE SUCTION TRUCK FOR YOUR REFERENCE.

VII. Shipping:RORO/BULK VESSEL/CONTAINER

RORO: The truck is pushed to the ship inside of immediately and set well. It can defend the truck currently being rusty and broken throughout transport.

BULK: The truck is lifted by crane then put on the vessel deck. This model is considerably more affordable.

CONTAINER: The truck is set into the container. This model is utilized for small model vans

VIII. ABOUT US

(1) More than five hundred staff, big and superior production

(2) 25 expert engineers, can provide the ideal and least expensive layout

(3) Build rigid QC group to ensure the good quality

(4) 1 12 months or thirty,000km guarantee which comes 1st.

(5) One particular set of spare areas of chassis presented which will aid you conserve income on maintenance.

(6) Offer technical assistance and right after serive for existence.

(7) Expert product sales team which will aid you to choose appropriate truck.

Best China manufacturer & factory china in Changwon Republic of Korea supplier St204 St205 St206 Plastic Stainless Steel Spherical Pillow Block Bearing With high quality best price

Meanwhile, our products are manufactured according to high quality standards, and complying with the international advanced standard criteria.

Overview

Quick Details

- Applicable Industries:

-

Manufacturing Plant

- Material:

-

Stainless Steel

- Application:

-

Agricultural Machinery

- Housing material:

-

Cast Iron HT200/ Ductile Iron

- Bearing Material:

-

100% Chrome Steel/GCr15

- Weight:

-

0.8kg

- Market:

-

Europe Asia Africa America

- Precision:

-

P0 P6 P5 P4 P2

- Model:

-

UC.UCP.UCF.UCT

- Feature:

-

Long Life

- Package:

-

Cartons

Supply Ability

- Supply Ability:

- 100000 Set/Sets per Month

Packaging & Delivery

- Packaging Details

- Neutral Packing or Our Own Brand Packing

Main products include: manure spreading truck, potato planting/harvesting machine, disc plough, disc harrow, grass Mower/slasher, corn and wheat thershers, seeder, mouldboard plow, deep subsoiler machines, rotary tiller, rear blade, fertilizer spreader, combine rice harvester, corn thresher, farm trailer, ridger, trencher, stubble cleaner, earth auger, cultivator and its accessories: Plow disc blades, harrowing film, plough tip and share, cultivator tine, casting parts etc.

- Port

- China any port

-

Lead Time

: -

Quantity(Bags) 1 – 100 >100 Est. Time(days) 7 To be negotiated

Online Customization

We – EPG – Ever power Transmission Co Ltd. is one of the biggest transmission company located in HangZhou near Xihu Lake.

We – EPG – Ever power Transmission Co Ltd. is one of the biggest transmission company located in HangZhou near Xihu Lake.

Product Description

Pillow Block Bearing introduction:

Bearing rings and rolling material with stainless steel AISI SUS440C(domestic number: 9Cr18Mo, 9Cr18) by vacuum quenching and tempering treatment, cage and ring frame material AISIO304 stainless steel(domestic number:1Cr18). Compared with ordinary stainless steel bearings bearing steel, a stronger anti-rust anti-corrosive, choose the right lubricant, dust cover, etc., can be used in an environment -60°C

~ +300’s. Stainless steel deep groove ball bearings can withstand moisture and corrosion caused by a number of other media. Such single row deep groove ball bearings and carbon chromium(rolling bearing) steel standard deep groove ball bearings, roller bearings with a deep ditch, with a high degree of bearing raceways and balls between. Stainless steel bearings because of high mechanical strength, high lThe EP Line PTO drive shafts are recognizable because of the EP Line patented coupling mechanism and the flexible cone. The PTO drive shafts are distinguished through user-friendliness, compactness and appealing design.oad capacity, widely used in food processing, medical equipment, pharmaceuticals machinery.

Applications:

1) Power Tools

2) Fans

3) Machines

4) Pumps

5) Electric Motors

6) Sport Apparaus

7) Textile Machined

8) Skateboard Skate

| Product | Stainless steel pillow block bearing |

| Precision Rating | ABEC1(P0) ABEC3(P6) ABEC5(P5) ABEC7(P4) ABEC9(P2) |

| Clearance | C2, C0, C3, C4, C5 |

| Model | ST series |

| OEM | Acceptable |

| Bearing Material | Stainless Steel 304, Chrome Steel |

| Housing Material | Stainless Steel 304 |

| Cage Material | Stainless Steel, Chrome Steel |

| Bore Size | 10-100 mm |

| Regular Export Packing | Card board package, pallet, wooden case or according to the requirements of the customers |

| MOQ | 1 pcs |

| Delivery Time | 3-7 days after receiving your payment |

| Payment Terms | L/C, T/T, Western Union, MoneyGram, Paypal |

| Port of shippment | Qingdao Port |

| Place of Origin | HangZhou,China |

Technology

Packaging & Shipping

Company Information

Enterprise culture

Vision: build up China’s high quality bearing manufacturer and product solution provider;

Mission: To build a platform for employees to realize their dreams, to provide customers with products to realize their values, and to create better and better services for the world;

Spirit: pragmatic, innovative, United and efficient.

Values:people-oriented, customer-oriented, technological innovation, quality improvement, teamwork, respect for employees, sharing results;

Service commitment: Free pre-sale, in-sale and after-sale technical advisory services, a cooperation, lifelong friends!

FAQ

SAMPLES

1.Samples quantity: 1-10 pcs are available.

2.Free samples: It depends on the model NO., material and quantity. Some of the bearings samples need client to pay

samples charge and shipping cost.

3.It’s better to start your order with Trade Assurance to get full protection for your samples order.

CUSTOMIZED

The customized LOGO or drawing is acceptable for us.

MOQ

1.MOQ: 10 pcs mix different standard bearings.

2.MOQ: 3000 pcs customized your brand bearings.

OEM POLICY

1.We can printing your brand (logo,artwork)on the shield or laser engraving your brand on the shield.

2.We can custom your packaging according to your design

3.All copyright own by clients and we promised don’t disclose any info.

SUPORT

Please visit our bearings website, we strongly encourge that you can communicate with us through email,thanks!

We have all kinds of bearings, just tell me your item number and quantity,best price will be offered to you soon

The material of the bearings, precision rating, seals type,OEM service,etc, all of them we can make according Series B Right Angle Worm GearEPG Drive Series B Right Angle Worm Gearto your requirement.

Contact US

Wechat/Whatsapp: +86 13083988828

Skype: [email protected]

Company Name: HangZhou EPG – One of the bigggest transmission manufacturer in China – Ever-Power Transmission Bearing Technology Co., Ltd

Office Address: Room B8F, Block B, shenhua road 789 – jianqiaogongshe International, XiHu District, HangZhou City,China

Cell: +86-13083988828

Factory Address: Bearing zone in XiHu County, HangZhou City, China

Best China manufacturer & factory china supplier Excavator Slewing Bearing 312C in stock With high quality best price

The high precise CNC equipment, such as Slow-feeding wire-cut machine, jig grinding machine and electric discharge machine, ensures the top quality precision of mould processing, with the high efficient and environmental protection acid rolling line being the largest raw material converting equipment in the field in china; The wildly use of automatic milling machine, high-speed automatic feeding punch, high speed automatic rolling and assembling machine guarantees the high quality and efficiency of components and chain making.

Overview

Quick Details

- Applicable Industries:

-

Building Material Shops, Manufacturing Plant, farms

- Brand Name:

-

OEM

- Application:

-

syf

- Precision:

-

ABEC3-5-7-9

- Gear:

-

Internal Gear

- Rolling element:

-

GCr15SiMn

- Material:

-

50Mn/42CrMo/Customized

- Operating tempereature:

-

syf

- Load direction:

-

Radial bearing

- RACEWAY hardness:

-

55~62HRC

- nner and outer ring modulation hardness:

-

229-268HB

- High operational efficiency:

-

compact design

Supply Ability

- Supply Ability:

- 1500 Set/Sets per Month

The company was certified by ISO9001:2008 Quality Management System.

Packaging & Delivery

- Packaging Details

- 1. Bearing surface is covered with the anti-rust oil first; And then wrapped with the plastic film;

2. And then packed with Kraft paper and professional belts;

3. At last, with wooden box totally at the outer packing to in void the rust or the moist;

4. Packaging can be done according to customer’s requirements.”>HGB Packaging Details:

1. Bearing surface is covered with the anti-rust oil first; And then wrapped with the plastic film;

2. And then packed with Kraft paper and professional belts;

3. At last, with wooden box totally at the outer packing to in void the rust or the moist;

4. Packaging can be done according to customer’s requirements.

- Port

- China any Port

-

Lead Time

: -

Quantity(Bags) 1 – 100 >100 Est. Time(days) 7 To be negotiated

Online Customization

Why Choose Us

Product Description

1,Single row four point contact ball slewing bearing

2,Single row cross roller slewinWorm-gear speed reducers have offered a rugged, adaptable, and cost-effective method of power transmission for nearly a century. But their acceptance in recent years has been somewhat diminished by inherent inefficiency and a reputation for eventually developing oil leaks. Extensive research into these two related issues has pinpointed several contributing factors:g bearing

3,Double-row ball slewing bearing

4,Three-row roller slewing bearing

5,Roller/Ball Combination Slewing bearing.

Single row four point

contact ball slewing bearing

Single row cross

roller slewing bearing

Double Row

Ball slewing bearing

Three row

roller slewing bearing

Roller/Ball Combination

Slewing bearing

|

Type |

• Single row four point contact ball slewing bearing |

|

Rollng elements |

Steel ball / Cylinder Roller |

|

Rollng elements Material |

GCr5/GCr15SiMn/Customized |

|

Bearing Material |

50Mn/42CrMo/42CrMo4V /Customized |

|

Cage Material |

Nylon/ steel /copper |

|

Structure |

taper pin , Mounting holes,Inner ring ,grease fitting,load plug, seals , roller ,spacer balls or separators |

|

Outer diameter |

50-10000mm |

|

Bore size |

50-10000mm |

|

Mounting hole |

Through hole/Tapped hole |

|

Raceway hardness |

55-62HRC |

|

Inner and outer ring modulation hardness |

229-269HB/Customized |

|

Gear type |

No gear ,Internal gear , External gear. |

|

Embellish grease |

EP2 lithium lubricating grease |

|

Certificate |

ABS.BV,DNV,ISO9001,GL |

|

Application area |

Ladle turret,Stacker crane,Bucket wheel machine,Solar heliostat Tracking System,port crane, Cabling machine,tower crane , offshore platform,ferris wheel, Palletizing robot,Rotary metallurgical furnace,can packing machine,Wind blade transporter,shield tunneling machine,tube push bench,excavator |

|

Brand Name |

HGB |

|

Place of Origin |

HangZhou Henan |

|

Warranty |

12 months |

|

Payment term |

T/T is our first choice |

|

Packing details |

1,Filling with anti-rust oil 2.Corved with Plastic paper 3.Corved with kThe quality of products is for us and for our customers of high significance. This is why we use European made components in our products. We also perform constant control of incoming materials and the control of finished products. In our company we work according to ISO 9001.raft paper 4.Corved with Blue tie 5.Put in wooden box |

Product Details

Bearing Parts

Steel ball/Roller:carbon-chromium bearing steel GCr15SiMn or GCr15 for rolling Material

Cage: include integral cage, segment cage and spacer-type cage. 20# steel or copper for integral and segment cages, PA 1010 resin or QA110-3-105 albronze for spacer-type cages.

Seals:uses NBR or VITON, few felted wool.

Single row cross roller slewing bearing

Composed of two or three rings. compact structure, light weight, high manufacturing accuracy, small assembly gap and high requirement for installation accuracy. Rollers are 1:1 cross-arranged.

Can be bear axial force, overturning moment and large radial force at the same time,and widely used in lifting transportation, construction machinery and military products.

Three row roller slewing bearing

Three row roller bearing able to bear all kinds of loads at the same time, it is the largest one of the four structural products with large axle and radial dimensions and firm structure. Especially suitable for heavy machinery requiring larger diameter, such as bucket wheel stacker and reclaimer, wheel crane, marine crane, port crane, ladle turret,large tonnage truck crane,heavy machinery and so on.

Single row four point contact ball slewing bearing

Single row four point composed of two seat rings. has compact structure, light weight, and four-point contact between steel ball and arc raceway. It can bear axial force, radial force and overturning moment at the same time. The construction machinery of rotary conveyor, welding manipulator, small and medium-sized crane and excavator can be selected.

More Products

Excavator Slewing Bearing

Three Row Roller Slewing Bearing

Brand Slewing Bearing

Certificate

About Us

Wide production workshop and strong production team as a support,ensure the products can be produced by required quality and quantity. andThereby increase the customer benefits.

The above is our production equipment with advanced technology , the stable and longevity bearing produce from these equipment .

We specialize in the production of manufacturing slewing ring bearings or turntable Bearings.The Independent R&D and sales team in HGB , also do our best for special needs;We offer high-precision and high-quality slewing bearings, which are widly used in many fields,such as hoisting and conveying machinery, construction engineering machinery, harbour machinery, wind power generation, radar and missile launchers and so on.

FAQ

1.Q: Are you trading company or manufacturer ?

A: We are professional slewing bearing manufacturer with 20 years’ experience.

2.Q: How long is your delivery time?

A: Generally it is 4-5 days if the goods are in stock. or it is 45 days if the goods are not in

stock, Also it is according to quantity.

3.Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample, it is extra.

4.Q: What is your terms of payment ?

A: Payment=1000USD, 30% T/T in advance, balance before shipment.

5.Q: Can you provide special customization according to the working conditions?

A: Sure, we can design and produce the slewing bearings for different working conditions.

6.Q: How about your guarantee?

A: We provide lifelong after-sales technical service.

Contact Us

Wechat/Whatsapp: +86 13083988828

Skype: +86 13083988828

Company Name: HangZhou EPG – One of the bigggest transmission manufacturer in China – Ever-Power Transmission Bearing Technology Co., Ltd

Office Address: Room B8F, Block B, shenhua road 789 – jianqiaogongshe International, XiHu District, HangZhou City,China

Phone: +86 13083988828

Factory Address: Bearing zone in XiHu County, HangZhou City, China