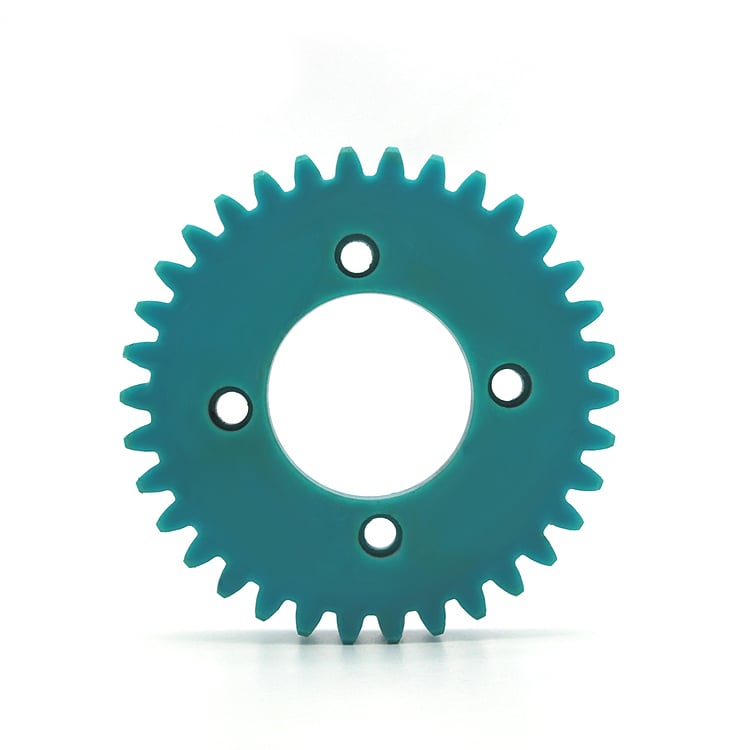

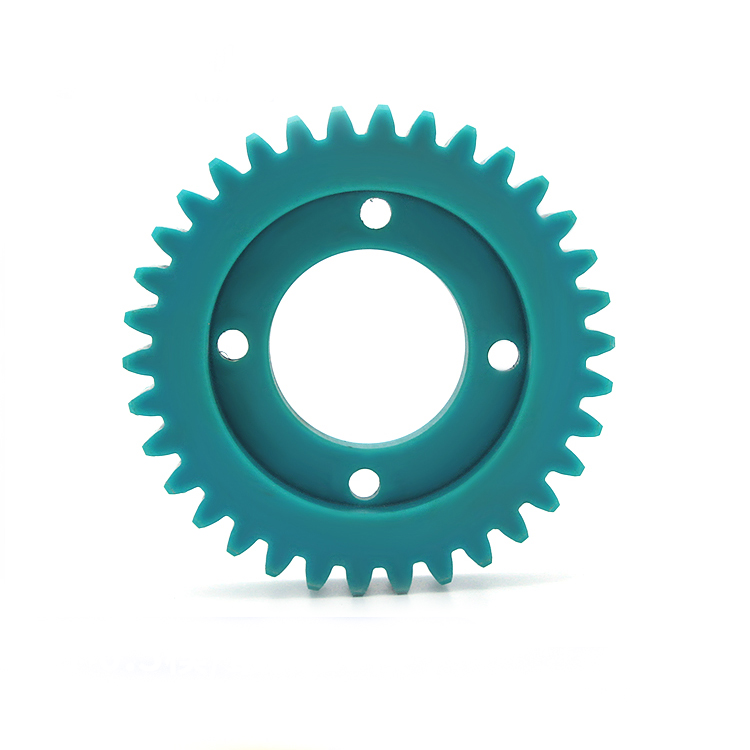

Product Description

Parameter specifications

| Certification | Shipment | Quality | material | Company System Certification |

| IATF16949 | in time | high | steel | ISO9001 |

Company Profile

HangZhou Xihu (West Lake) Dis. East Port Gear Manufacturing factory is located in Zhoujia Industrial Zone, CHINAMFG Town, HangZhou, 3km away from Xihu (West Lake) Dis.qian Lake. It focuses on precision gear research, development, production and sales. The factory has obtained ISO9001: 2015 certificate, IATF16949:2016. The main export markets were North America, South America and Europe. Products can be customized and mainly includes: New Energy Motor Shaft, Oil Pump Gear, Agricultural Machinery Gear, Transmission Gear, Electric Vehicle gear, etc. We are sincerely willing to cooperate with enterprises from all over the world.

Equipment And Main Products

Certifications

FAQ

Q1:How is the quality of your product?

A:Our product has reliable quality, high wear life

Q2:Customization process/work flow?

Advisory – Material selection – 2D/3D Drawing – Quotation – Payment – Production – Quality Control – Package – Delivery

Q3: What is your terms of packing?

A:Generally, we pack our goods in wooden cases, If you have special request about packing, pls negotiate with us in advance, we can pack the goods as your request.

Q4:Price?

A:We will offer competitive price after receiving your drawing

Q5:What is your terms of payment?

A:30% T/T advanced, 70% T/T before shipping

Q6:What is your terms of delivery?

A: FOB

Q7:What drawing software does your company use?

A:CAXA

Q8:Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q9:How about your delivery time?

A:Product can often be delivered within 40-90 days

Q10:Sample?

A:We offer paid sample.If you have sample requirements, please feel free to contact us at any time

Q11:What logistics packaging does your company use?

A:Express for urgent orders. UPS, FedEx, DHL, TNT, EMS.

Q12:Application range?

A:Automotive, medical, automation, agricultural, marine, etc.

Q13: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them,

no matter where they come from.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Agricultural Machinery, Car |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | External Gear |

| Samples: |

US$ 50/Piece

1 Piece(Min.Order) | Order Sample customized version

|

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

What maintenance practices are essential for prolonging the lifespan of PTO shafts?

Maintaining proper care and performing regular maintenance on Power Take-Off (PTO) shafts is crucial for prolonging their lifespan and ensuring optimal performance. By following essential maintenance practices, you can prevent premature wear, identify potential issues early on, and maximize the longevity of your PTO shafts. Here are some key maintenance practices to consider:

1. Regular Inspection: Perform routine visual inspections of the PTO shaft to check for any signs of damage, wear, or misalignment. Look for cracks, dents, bent sections, or loose components. Inspect the universal joints, coupling mechanisms, protective guards, and other associated parts. Pay attention to any unusual noises, vibrations, or changes in performance, as these can indicate underlying issues that require attention.

2. Lubrication: Proper lubrication is essential for the smooth operation and longevity of PTO shafts. Follow the manufacturer’s recommendations regarding lubrication intervals and use the recommended lubricant type. Apply lubrication to the universal joints, CV joints (if applicable), and other moving parts as specified. Regularly check for adequate lubricant levels and replenish if necessary. Ensure that the lubricant used is compatible with the shaft material and does not attract dirt or debris that could cause abrasion or damage.

3. Cleaning: Keep the PTO shaft clean and free from dirt, debris, and other contaminants. Regularly remove any accumulated dirt, grease, or residue using a brush or compressed air. Be particularly diligent in cleaning the universal joints and areas where the shaft connects to other components. Cleaning prevents the buildup of abrasive particles that can accelerate wear and compromise the shaft’s performance.

4. Guard Inspection and Maintenance: Check the protective guards and shields regularly to ensure they are securely in place and free from damage. Guards play a critical role in preventing accidental contact with the rotating shaft and minimizing the risk of injury. Repair or replace any damaged or missing guards promptly. Ensure that the guards are correctly aligned and provide sufficient coverage for all moving parts of the PTO shaft.

5. Torque and Fastener Checks: Periodically inspect and check the torque of fasteners, such as bolts and nuts, that secure the PTO shaft and associated components. Over time, vibration and normal operation can loosen these fasteners, compromising the integrity of the shaft. Use the appropriate torque specifications provided by the manufacturer to ensure proper tightening. Regularly verify the tightness of fasteners and retighten as necessary.

6. Shear Bolt or Slip Clutch Maintenance: If your PTO shaft incorporates shear bolt or slip clutch mechanisms, ensure they are functioning correctly. Inspect the shear bolts for signs of wear or damage, and replace them when necessary. Check the slip clutch for proper adjustment and smooth operation. Follow the manufacturer’s recommendations regarding maintenance and adjustment of these safety mechanisms to ensure their effectiveness in protecting the driveline components.

7. Proper Storage: When the PTO shaft is not in use, store it in a clean and dry environment. Protect the shaft from exposure to moisture, extreme temperatures, and corrosive substances. If possible, store the shaft in a vertical position to prevent bending or distortion. Consider using protective covers or cases to shield the shaft from dust, dirt, and other potential sources of damage.

8. Operator Training: Provide proper training to operators on the correct operation, maintenance, and safety procedures related to the PTO shafts. Educate them about the importance of regular inspections, lubrication, and adherence to recommended maintenance practices. Encourage operators to report any abnormalities or concerns promptly to prevent further damage and ensure timely repairs or adjustments.

9. Manufacturer and Expert Guidance: Consult the manufacturer’s guidelines and recommendations regarding maintenance practices specific to your PTO shaft model. Additionally, seek advice from experts or authorized service technicians who are knowledgeable about PTO shaft maintenance. They can provide valuable insights and assistance in implementing the best maintenance practices for your specific PTO shafts.

By following these maintenance practices, you can extend the lifespan of your PTO shafts, optimize their performance, and reduce the likelihood of unexpected failures or costly repairs. Regular inspections, lubrication, cleaning, guard maintenance, torque checks, and proper storage are all essential in ensuring the longevity and reliability of your PTO shafts.

How do PTO shafts handle variations in load and torque during operation?

PTO (Power Take-Off) shafts are designed to handle variations in load and torque during operation by employing specific mechanisms and features that ensure efficient power transfer and protection against overload conditions. Here’s a detailed explanation of how PTO shafts handle variations in load and torque:

1. Mechanical Design: PTO shafts are engineered with robust mechanical design principles that enable them to handle variations in load and torque. They are typically constructed using high-strength materials such as steel, which provides durability and resistance to bending or twisting forces. The shaft’s diameter, wall thickness, and overall dimensions are carefully calculated to withstand the expected torque levels and load variations. The mechanical design of the PTO shaft ensures that it can transmit power reliably and accommodate the dynamic forces encountered during operation.

2. Universal Joints: Universal joints are a key component of PTO shafts that allow for flexibility and compensation of misalignment between the power source and driven machinery. These joints can accommodate variations in angular alignment, which may occur due to changes in load or movement of the machinery. Universal joints consist of a cross-shaped yoke with needle bearings that allow for smooth rotation and transfer of torque, even when the shafts are not perfectly aligned. The design of universal joints enables PTO shafts to handle variations in load and torque while maintaining consistent power transmission.

3. Slip Clutches: Slip clutches are often incorporated into PTO shafts to provide overload protection. These clutches allow the PTO shaft to slip or disengage momentarily when excessive torque or resistance is encountered. Slip clutches typically consist of friction plates that can be adjusted to a specific torque setting. When the torque surpasses the predetermined limit, the clutch slips, preventing damage to the PTO shaft and connected equipment. Slip clutches are particularly useful when sudden changes in load or torque occur, providing a safety mechanism to protect the PTO shaft and associated machinery.

4. Torque Limiters: Torque limiters are another protective feature found in some PTO shafts. These devices are designed to automatically disengage the power transmission when a predetermined torque threshold is exceeded. Torque limiters can be mechanical, such as shear pin couplings or friction clutches, or electronic, utilizing sensors and control systems. When the torque exceeds the set limit, the torque limiter disengages, preventing further power transfer and protecting the PTO shaft from overload conditions. Torque limiters are effective in handling sudden spikes in torque and safeguarding the PTO shaft and associated equipment.

5. Maintenance and Inspection: Regular maintenance and inspection of PTO shafts are essential to ensure their proper functioning and ability to handle variations in load and torque. Routine maintenance includes lubrication of universal joints, inspection of shaft integrity, and tightening of fasteners. Regular inspections allow for early detection of wear, misalignment, or other issues that may affect the PTO shaft’s performance. By addressing maintenance and inspection requirements, operators can identify and address any concerns that may arise due to variations in load and torque, ensuring the continued safe and efficient operation of the PTO shaft.

6. Operator Awareness and Control: Operators play a crucial role in managing variations in load and torque during PTO shaft operation. They should be aware of the machinery’s operational limits, including the recommended torque ratings and load capacities of the PTO shaft. Proper training and understanding of the equipment’s capabilities enable operators to make informed decisions and adjust the operation when encountering significant load or torque changes. Operators should also be vigilant in monitoring the equipment’s performance, watching for any signs of excessive vibration, noise, or other indications of potential issues related to load and torque variations.

By incorporating robust mechanical design, utilizing universal joints, slip clutches, torque limiters, and implementing proper maintenance practices, PTO shafts are equipped to handle variations in load and torque during operation. These features ensure reliable power transmission, protect against overload conditions, and contribute to the safe and efficient functioning of the PTO shaft and the machinery it drives.

Can you explain the different types of PTO shafts and their applications?

PTO shafts (Power Take-Off shafts) come in various types, each designed for specific applications and requirements. The different types of PTO shafts offer versatility and compatibility with a wide range of machinery and implements. Here’s an explanation of the most common types of PTO shafts and their applications:

1. Standard PTO Shaft: The standard PTO shaft, also known as a splined shaft, is the most common type used in agricultural and industrial machinery. It consists of a solid steel shaft with splines or grooves along its length. The standard PTO shaft typically has six splines, although variations with four or eight splines can be found. This type of PTO shaft is widely used in tractors and various implements, including mowers, balers, tillers, and rotary cutters. The splines provide a secure connection between the power source and the driven machinery, ensuring efficient power transfer.

2. Shear Bolt PTO Shaft: Shear bolt PTO shafts are designed with a safety feature that allows the shaft to separate in case of overload or sudden shock to protect the driveline components. These PTO shafts incorporate a shear bolt mechanism that connects the tractor’s power take-off to the driven machinery. In the event of excessive load or sudden resistance, the shear bolt is designed to break, disconnecting the PTO shaft and preventing damage to the driveline. Shear bolt PTO shafts are commonly used in equipment that may encounter sudden obstructions or high-stress situations, such as wood chippers, stump grinders, and heavy-duty rotary cutters.

3. Friction Clutch PTO Shaft: Friction clutch PTO shafts feature a clutch mechanism that allows for smooth engagement and disengagement of the power transfer. These PTO shafts typically incorporate a friction disc and a pressure plate, similar to a traditional vehicle clutch system. The friction clutch allows operators to gradually engage or disengage the power transfer, reducing shock loads and minimizing wear on the driveline components. Friction clutch PTO shafts are commonly used in applications where precise control of power engagement is required, such as in hydraulic pumps, generators, and industrial mixers.

4. Constant Velocity (CV) PTO Shaft: Constant Velocity (CV) PTO shafts, also known as homokinetic shafts, are designed to accommodate high angles of misalignment without affecting power transmission. They use a universal joint mechanism that allows for smooth power transfer even when the driven machinery is at an angle relative to the power source. CV PTO shafts are frequently used in applications where the machinery requires a significant range of movement or articulation, such as in articulated loaders, telescopic handlers, and self-propelled sprayers.

5. Telescopic PTO Shaft: Telescopic PTO shafts are adjustable in length, allowing for flexibility in equipment configuration and varying distances between the power source and the driven machinery. They consist of two or more concentric shafts that slide within each other, providing the ability to extend or retract the PTO shaft as needed. Telescopic PTO shafts are commonly used in applications where the distance between the tractor’s power take-off and the implement varies, such as in front-mounted implements, snow blowers, and self-loading wagons. The telescopic design enables easy adaptation to different equipment setups and minimizes the risk of the PTO shaft dragging on the ground.

6. Gearbox PTO Shaft: Gearbox PTO shafts are designed to adapt power transmission between different rotational speeds or directions. They incorporate a gearbox mechanism that allows for speed reduction or increase, as well as the ability to change rotational direction. Gearbox PTO shafts are commonly used in applications where the driven machinery requires a different speed or rotational direction than the tractor’s power take-off. Examples include grain augers, feed mixers, and industrial equipment that requires specific speed ratios or reversing capabilities.

It’s important to note that the availability and specific applications of PTO shaft types may vary based on regional and industry-specific factors. Additionally, certain machinery or implements may require specialized or custom PTO shafts to meet specific requirements.

In summary, the different types of PTO shafts, such as standard, shear bolt, friction clutch, constant velocity (CV), telescopic, and gearbox shafts, offer versatility and compatibility with various machinery and implements. Each type of PTO shaft is designed to address specific needs, such as power transfer efficiency, safety, smooth engagement, misalignment tolerance, adaptability, and speed/direction adjustment. Understanding the different types of PTO shafts and their applications is crucial for selecting the appropriate shaft forthe intended machinery and ensuring optimal performance and reliability.

editor by CX 2024-02-18

China Custom Gear and Worm Gearbox/Agricultural Machinery/Hardware/Planetary Gears CNC Machining/Drive Gears Pto and Transmission Shaft 99

Product Description

Parameter specifications

| Certification | Shipment | Quality | material | Company System Certification |

| IATF16949 | in time | high | steel | ISO9001 |

Company Profile

HangZhou Xihu (West Lake) Dis. East Port Gear Manufacturing factory is located in Zhoujia Industrial Zone, CHINAMFG Town, HangZhou, 3km away from Xihu (West Lake) Dis.qian Lake. It focuses on precision gear research, development, production and sales. The factory has obtained ISO9001: 2015 certificate, IATF16949:2016. The main export markets were North America, South America and Europe. Products can be customized and mainly includes: New Energy Motor Shaft, Oil Pump Gear, Agricultural Machinery Gear, Transmission Gear, Electric Vehicle gear, etc. We are sincerely willing to cooperate with enterprises from all over the world.

Equipment And Main Products

Certifications

FAQ

Q1:How is the quality of your product?

A:Our product has reliable quality, high wear life

Q2:Customization process/work flow?

Advisory – Material selection – 2D/3D Drawing – Quotation – Payment – Production – Quality Control – Package – Delivery

Q3: What is your terms of packing?

A:Generally, we pack our goods in wooden cases, If you have special request about packing, pls negotiate with us in advance, we can pack the goods as your request.

Q4:Price?

A:We will offer competitive price after receiving your drawing

Q5:What is your terms of payment?

A:30% T/T advanced, 70% T/T before shipping

Q6:What is your terms of delivery?

A: FOB

Q7:What drawing software does your company use?

A:CAXA

Q8:Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q9:How about your delivery time?

A:Product can often be delivered within 40-90 days

Q10:Sample?

A:We offer paid sample.If you have sample requirements, please feel free to contact us at any time

Q11:What logistics packaging does your company use?

A:Express for urgent orders. UPS, FedEx, DHL, TNT, EMS.

Q12:Application range?

A:Automotive, medical, automation, agricultural, marine, etc.

Q13: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them,

no matter where they come from.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Agricultural Machinery, Car |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | Internal Gear |

| Samples: |

US$ 50/Piece

1 Piece(Min.Order) | Order Sample customized version

|

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How do PTO shafts ensure efficient power transfer while maintaining safety?

PTO (Power Take-Off) shafts play a crucial role in ensuring efficient power transfer from a power source to driven machinery or equipment, while also maintaining safety. These shafts are designed with various features and mechanisms to optimize power transmission efficiency and mitigate potential hazards. Here’s a detailed explanation of how PTO shafts achieve efficient power transfer while prioritizing safety:

1. Mechanical Power Transmission: PTO shafts serve as mechanical linkages between the power source, typically a tractor or engine, and the driven machinery. They transmit rotational power from the power source to the equipment, enabling efficient transfer of energy. The mechanical design of PTO shafts, including their diameter, length, and material composition, is optimized to minimize power losses during transmission, ensuring that a significant portion of the power generated by the source is effectively delivered to the machinery.

2. Universal Joints and Flexible Couplings: PTO shafts are equipped with universal joints and flexible couplings that allow for angular misalignment and flexibility in movement. Universal joints accommodate variations in the alignment between the power source and the driven machinery, enabling smooth power transfer even when the two components are not perfectly aligned. Flexible couplings help to compensate for slight misalignments, reduce vibration, and prevent excessive stress on the shaft and connected components, thereby enhancing efficiency and reducing the risk of mechanical failure or damage.

3. Constant Velocity (CV) Joints: CV joints are often used in PTO shafts to maintain constant speed and torque transfer, particularly in applications where the driven machinery requires flexibility or operates at different angles. CV joints allow for smooth power transmission without significant fluctuations, even when the driven machinery is at an angle relative to the power source. By minimizing speed variations and power loss due to changing angles, CV joints contribute to efficient power transfer while ensuring consistent performance and reducing the likelihood of mechanical stress or premature wear.

4. Safety Guards and Shields: Safety is a paramount consideration in the design of PTO shafts. Protective guards and shields are installed to cover the rotating shaft and other moving parts. These guards act as physical barriers to prevent accidental contact with the rotating components, significantly reducing the risk of entanglement, injury, or damage. Safety guards are typically made of durable materials such as metal or plastic and are designed to allow the necessary movement for power transmission while providing adequate protection. Regular inspection and maintenance of these guards are crucial to ensure their effectiveness in maintaining safety.

5. Shear Bolt or Slip Clutch Mechanisms: PTO shafts often incorporate shear bolt or slip clutch mechanisms as safety features to protect the driveline components and prevent damage in case of excessive torque or sudden resistance. Shear bolts are designed to shear or break when the torque exceeds a predetermined threshold, disconnecting the PTO shaft from the power source. This helps prevent damage to the shaft, driven machinery, and power source. Slip clutches work similarly by allowing the PTO shaft to slip when excessive resistance is encountered, protecting the components from overload. These mechanisms act as safety measures to maintain the integrity of the PTO shaft and associated equipment while minimizing the risk of mechanical failures or accidents.

6. Compliance with Safety Standards: PTO shafts are designed and manufactured to comply with relevant safety standards and regulations. Manufacturers follow guidelines and requirements set by organizations such as the American Society of Agricultural and Biological Engineers (ASABE) or other regional safety authorities. Compliance with these standards ensures that PTO shafts meet specific safety criteria, including torque capacity, guard design, and other safety considerations. Users can rely on standardized PTO shafts that have undergone testing and certification, providing an additional layer of assurance regarding their safety and performance.

7. Operator Education and Training: To ensure safe and efficient operation, it is essential for operators to receive proper education and training on PTO shafts. Operators should be familiar with the specific safety features, maintenance requirements, and safe operating procedures for the PTO shafts used in their applications. This includes understanding the importance of using appropriate personal protective equipment, regularly inspecting the equipment for wear or damage, and following recommended maintenance schedules. Operator awareness and adherence to safety protocols significantly contribute to maintaining a safe working environment and maximizing the efficiency of power transfer.

In summary, PTO shafts ensure efficient power transfer while maintaining safety through their mechanical design, incorporation of universal joints and CV joints, installation of safety guards and shields, implementation of shear bolt or slip clutch mechanisms, compliance with safety standards, and operator education. By combining these features and practices, PTO shafts provide reliable and secure power transmission, minimizing power losses and potential risks associated with their operation.

Can you provide real-world examples of equipment that use PTO shafts?

Power Take-Off (PTO) shafts are extensively used in various industries, particularly in agriculture and construction. They provide a reliable power source for a wide range of equipment, enabling efficient operation and increased productivity. Here are some real-world examples of equipment that commonly use PTO shafts:

1. Agricultural Machinery:

- Tractor Implements: A wide array of tractor-mounted implements rely on PTO shafts for power transfer. These include:

- Mowers and rotary cutters

- Balers and hay equipment

- Tillers and cultivators

- Seeders and planters

- Sprayers

- Manure spreaders

- Harvesters, such as combine harvesters and forage harvesters

- Stationary Equipment: PTO shafts are also used in stationary agricultural equipment, including:

- Feed grinders and mixers

- Silo unloaders

- Grain augers and elevators

- Irrigation pumps

- Wood chippers and shredders

- Stump grinders

2. Construction and Earthmoving Equipment:

- Backhoes and Excavators: PTO shafts can be found in backhoes and excavators, powering attachments such as augers, hydraulic hammers, and brush cutters.

- Post Hole Diggers: Post hole diggers used for fence installation often rely on PTO shafts to transfer power to the digging mechanism.

- Trenchers: Trenching machines equipped with PTO shafts efficiently dig trenches for utility installations, drainage systems, or irrigation lines.

- Stump Grinders: Stump grinders used in land clearing and tree removal operations often utilize PTO shafts to power their cutting blades.

- Soil Stabilizers and Road Reclaimers: These machines use PTO shafts to drive the rotor and milling drums, which pulverize and mix materials for road construction and maintenance.

3. Forestry Equipment:

- Wood Chippers: Wood chippers used for processing tree branches and logs into wood chips are commonly powered by PTO shafts.

- Brush Cutters and Mulchers: PTO-driven brush cutters and mulchers are employed to clear vegetation and maintain forested areas.

- Log Splitters: Log splitters that split logs into firewood often utilize PTO shafts to power the splitting mechanism.

4. Utility Equipment:

- Generators: Some generators are designed to be driven by PTO shafts, providing an auxiliary power source for various applications in remote locations or during power outages.

- Pumps: PTO-driven pumps are commonly used for agricultural irrigation, water transfer, and dewatering applications.

5. Specialty Equipment:

- Ice Resurfacers: PTO shafts are employed in ice resurfacing machines used in ice rinks to maintain a smooth ice surface for ice hockey and figure skating.

- Air Compressors: Some air compressors are driven by PTO shafts, providing a source of compressed air for various applications.

These examples represent a range of equipment that extensively relies on PTO shafts for power transfer. PTO shafts enable the efficient operation of these machines, increasing productivity and versatility across various industries.

What benefits do PTO shafts offer for various types of machinery?

PTO shafts (Power Take-Off shafts) offer several benefits for various types of machinery in agricultural and industrial applications. They provide a flexible and efficient means of power transmission, enabling machinery to perform specific tasks and functions. Here’s a detailed explanation of the benefits that PTO shafts offer for different types of machinery:

Versatility: PTO shafts contribute to the versatility of machinery by allowing them to be powered by a common power source, such as a tractor or an engine. This means that a single power source can be used to drive multiple implements or machines by simply connecting and disconnecting the PTO shaft. For example, in agriculture, a tractor equipped with a PTO shaft can power various implements such as mowers, balers, tillers, sprayers, and grain augers. Similarly, in industrial applications, PTO shafts enable the use of a single engine or motor to power different machines or equipment, such as generators, pumps, compressors, and industrial mixers.

Efficiency: PTO shafts offer an efficient method of power transfer from the power source to the machinery. By directly connecting the power source to the driven machine, PTO shafts minimize energy losses that may occur with other power transmission methods. This direct power transfer results in improved overall efficiency and performance of the machinery. Additionally, PTO shafts allow for the adjustment of rotational speed and power output to match the requirements of the specific machinery, ensuring optimal operation and reducing unnecessary energy consumption.

Cost Savings: The use of PTO shafts can lead to cost savings in multiple ways. Firstly, by utilizing a single power source to drive multiple machines or implements, the need for separate engines or motors for each piece of equipment is eliminated, reducing capital costs. Secondly, PTO shafts eliminate the requirement for additional fuel or energy sources, as they tap into the existing power source, resulting in lower fuel or energy expenses. Additionally, the versatility offered by PTO shafts allows for improved equipment utilization, maximizing the return on investment.

Flexibility: PTO shafts provide flexibility in terms of equipment setup and configuration. They can be adjusted in length or equipped with telescopic sections, allowing for easy adaptation to different equipment arrangements and varying distances between the power source and the driven machinery. This flexibility enables operators to quickly connect and disconnect the PTO shafts as needed, facilitating efficient equipment changes and reducing downtime. Moreover, the ability to adjust the rotational speed and power output of the PTO shafts adds further flexibility, accommodating the specific requirements of different machinery and applications.

Ease of Use: PTO shafts are relatively easy to use, making them accessible to operators with minimal training. The process of connecting and disconnecting the PTO shafts is straightforward, often involving a simple coupling or locking mechanism. This ease of use enhances equipment operability, allowing operators to quickly switch between different implements or machines without significant effort or time-consuming procedures. Furthermore, the direct power transfer through PTO shafts simplifies equipment operation, as the machinery can be powered by the existing power source without the need for additional controls or power management systems.

Increased Productivity: PTO shafts contribute to increased productivity in agricultural and industrial operations. By enabling the use of versatile machinery configurations, operators can perform a wide range of tasks using a single power source. This eliminates the need for manual labor or the use of multiple machines, streamlining workflow and reducing the time required to complete various operations. The efficiency and reliability of power transfer through PTO shafts also contribute to improved productivity by ensuring consistent and effective operation of machinery, resulting in enhanced output and reduced downtime.

Safety: While not directly related to machinery performance, PTO shafts also offer safety benefits. The implementation of safety shields or guards on PTO shafts helps prevent accidental contact with the rotating shaft, reducing the risk of injuries to operators. These safety features are designed to cover the rotating shaft and universal joints, ensuring that operators cannot come into contact with them during operation. Proper training on PTO shaft operation and adherence to safety guidelines further enhance operator safety when working with PTO-driven machinery.

In summary, PTO shafts offer a range of benefits for various types of machinery. These benefits include increased versatility, improved efficiency, cost savings, flexibility in equipment configurations, ease of use, increased productivity, and enhanced operator safety. PTO shafts play a crucial role in agricultural and industrial applications by enabling the direct power transfer from a common power source to different machines or implements, resulting in optimized performance and operational effectiveness.

editor by CX 2024-01-09

Industrial made in China – replacement parts – in Misratah Libya Sprocket Transmission Precision Parts Automotive Gears for Transmission Planetary Transmission Starter Gear Spur Gear Z12 with ce certificate top quality low price

We – EPG Team the bigge EPT Chain and agricultural gearbox manufacturing unit in China with 5 different branches. For far more particulars: Mobile/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

Items description

|

Product Type |

M0.5~M12, Z8~80. regular equipment, or in accordance consumer drawing to make. |

|

Materials: |

Carbon Steel, Brass, Aluminium, Stainless steel, Plastic, POM, Delrin, Titanium Alloy etc. |

|

Process method |

CNC Turning, milling ,drilling, grinding etc. |

|

Surface finish: |

Chrome plating, Anodization, Powder coating, blackening, Sand blasting, Brushing & ploshing,Electrophoresis etc. |

|

OEM & ODM Service |

Obtainable |

|

Design Software |

Pro/E, Auto CAD, Solid Works |

|

Trade Terms: |

FOB,,CIF,EXW |

|

Payment Terms: |

T/T, L/C, |

|

Packing: |

Foam, Carton, Standard Wooden boxes |

|

Ability |

8,000~1,5000 pcs per month |

|

Delivery |

20-30 days after receiving PO |

|

Purposes |

Automotive Parts,hydraulics, compressors,Industrial equipments, transmission parts, etc. |

|

Our services: |

CNC Machining, Milling, Stamping, Sheet metal fabricating, and Die-Casting |

Our Company

Gear inspection

FAQ

Q1. What is your conditions of packing?

A: Generally, we pack our items in one shade box. If you have unique reque EPT about packing, p EPT negotiate with us in advance, we can pack the merchandise as your request.

Q2. What is your phrases of payment?

A: T/T thirty% as deposit, and 70% ahead of supply. We are going to present you the pictures of the goods and packages

prior to you spend the balance. EPT payments conditions, p EPT negotiate with us in progress, we can examine.

Q3. What is your phrases of delivery?

A: EXW, FOB, CFR, CIF.

This fall. How about your supply time?

A: Generally, it will get 25 to thirty times right after receiving your advance payment. The certain delivery time depends

on the things and the amount of your get.

Q5. Can you generate according to the samples?

A: Yes, we can create by your samples or technical drawings. We can build the molds and fixtures.

Q6. What is your sample coverage?

A: We can source the sample if we have completely ready components in inventory, but the clients have to pay out the sample co EPT and

the courier value.We welcome sample buy.

Q7. Do you te EPT all your goods before supply?

A: Indeed, we have 100% te EPT before shipping and delivery

Q8: How do you make our company long-time period and excellent romantic relationship?

1. We hold great good quality and competitive value to make certain our consumers benefit

two. We regard each client as our good friend and we sincerely do company and make friends with them,

no issue exactly where they appear from.

The use of authentic tools manufacturer’s (OEM) component quantities or logos , e.g. CASE® and John Deere® are for reference purposes only and for indicating product use and compatibility. Our company and the outlined substitution elements contained herein are not sponsored, accepted, or created by the OEM.

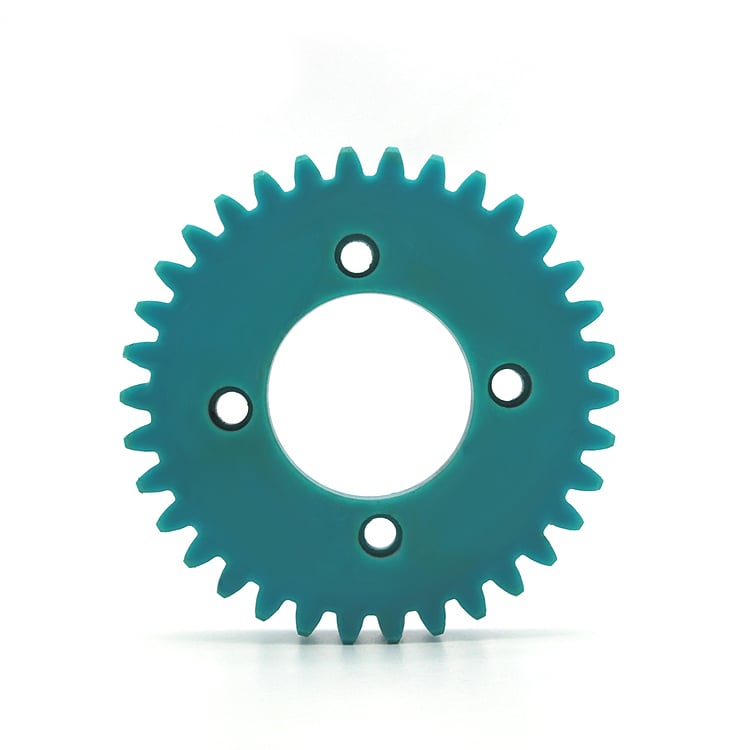

Best China manufacturer & factory China Nice Quality High strength plastic Non-toxic circular pitch cp nylon gears With high quality best price

Having accumulated precious experience in cooperating with foreign customers, a specialized supplier of a full range of chains, sprockets, gears, gear racks, V-belts, couplings and reducers, pto shaft, agricultural gearboxes….

Overview

Quick Details

- Material:

-

Zinc, ALLOY, Titanium, STAINLESS STEEL

- Product name:

-

plastic Non-toxic circular pitch cp nylon gears

- Place of Orign:

-

JIANGSU China (Mainland)

- Colour:

-

Black/green/blue/beige/white

Packaging & Delivery

- Port

- nb

-

Lead Time

: -

Quantity(Bags) 1 – 1000 >1000 Est. Time(days) 3 To be negotiated

The PTO shaft included with all Victory Tractor mowers has a longer extension than the typical PTO Shaft. The added length is necessary because of the far reaching movement of the mowers to the right of the tractor.

Online Customization

EPG offers customers of all sizes complete custom metal fabrication services with unique processes, which streamlines designing, analyzing, pricing and ordering your custom parts from short runs to long production contracts. The processes we provide: Machining, Milling, Turning, Metal stamping, Sheet metal, and finishes, etc. 100% quality manufacturing. We guarantee that our products meet your supplied specifications Extremely competitive pricing Delivery to your port oA novel design that uses a simple coil spring mounted in the breather’s air passageway solves the problem. The interior of the spring does not provide a continuous surface where bubbles can form, and this eliminates the percolating effect and resulting oil transfer.r front door 48 week lead times We handle all paperworkPartial container orders Flexible payment options Unique tooling options Full range of packaging options from bulk to retail ready

Product Description

China Nice Quality High strength plastic Non-toxic circular pitch cp nylon gears

Our services:

(a) Good after-sale service, all questions will be replied within 12 hours.

(b) Customized design is available. ODM&OEM are welcomed.

(c) We can provide free sample, consumer should pay the freight first.

(d) Convenient transportation and fast delivery, all available shipping ways could be applied, by express, air or sea.

(e) High quality and most competitive price.

(f) Advanced produce and inspecting equipments.

Contact us:

Welcome to contact us, we will do our best to help you!

Whatsapp:+86-13083988828

Tel:+86-13083988828 or +86-13858117778