Product Description

HangZhou CHINAMFG Machinery Factory

Product Technical Parameter

Product description:Using casting process, more durable,Just need to provide a simple size measurement to quote

Product Images:

detail:We’ve already got Triangular profile tube and Lemon profile tube for all the series we provide.Various protective cases

tube: 16Mn condensing pipe (strong toughness, good wear resistance)

yoke: Triangular tube 45# steel Forgings (with positive heat treatment)

cross kit: 20CrMnTi Forgings (product through normalizing, carbon heat treatment)

raw material:

Packing & shipping:

We ship a large number of goods to the United States, Russia, Mexico, South America, Southeast Asia and other regions.

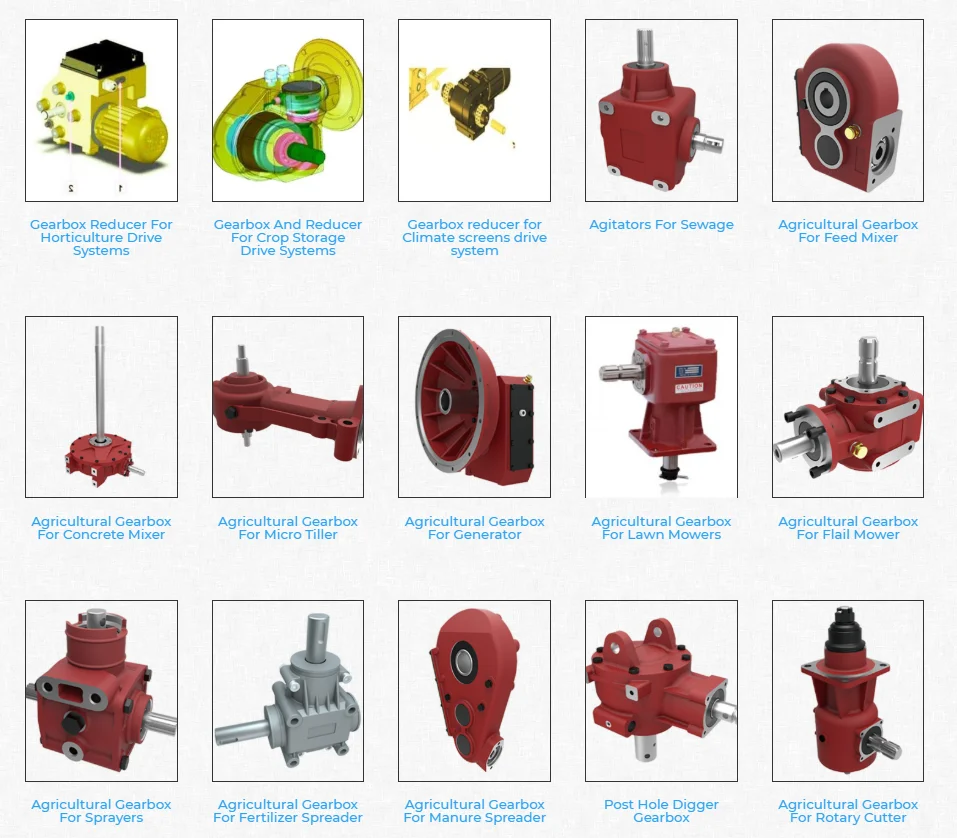

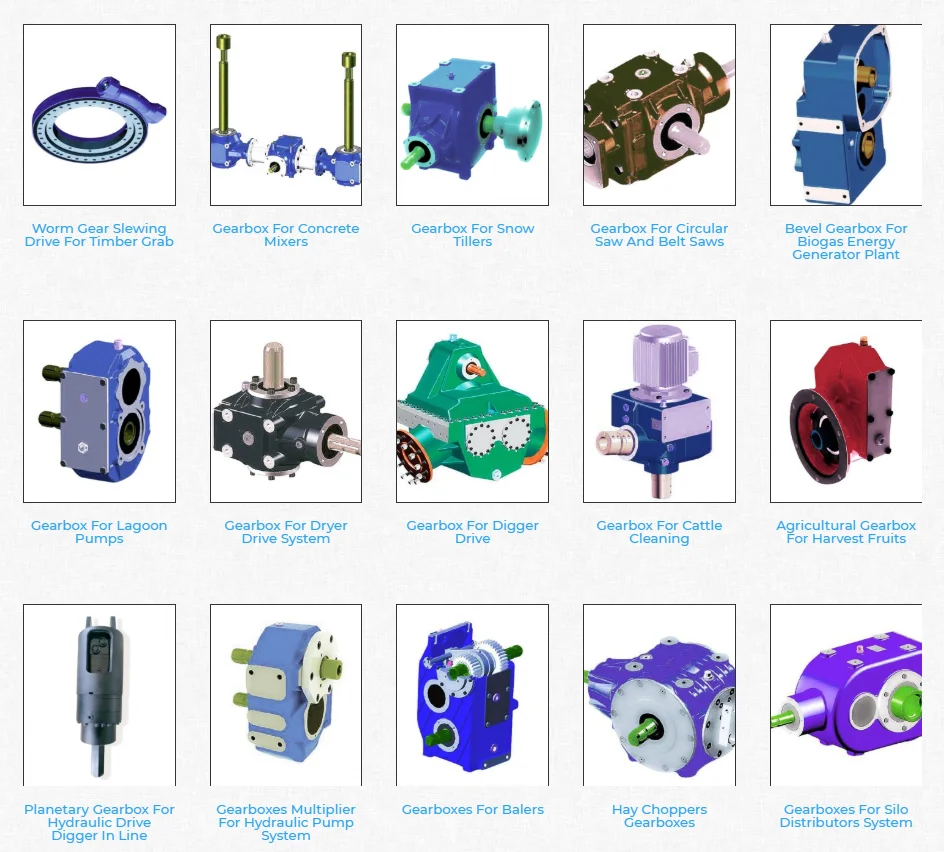

Other Products:

Our Company :

| Business type | Manufacture |

| Location | Shiliwang Industrial Zone of HangZhou, ZheJiang ,China |

| Year Established | 2003 |

| Occupied area | 50 Acres |

| Company certification | CE, ISO9001,SGS |

| Main product | disc harrow, disc plough, trailer, boom sprayer , rotary tillers, potato planter ,plowing blade, plough blade, soil-loosening shovel and so on. With good quality, excellent performance, our products annually export to countries around the world, and we have gained the majority of customers trust. |

FAQ:

1.Q: Full price list for these products

A: If you need the price list for these products, please notify the product model so that I can quote you accordingly. Please understand we have a very wide product range, we don’t usually offer full products price list.

2. Q: Business terms

A: Shipment time: 25-40days after your payment

Shipment: By sea

Loading port: HangZhou port, China

Destination port: …To be advised

Payment: T/T

Warranty: 1 year

3.Q:How can I order from you?

A: Please send us your enquiry list; we will reply you within 2 working days.

4.Q:If the finger I look for are not in your catalogue, what should I do?

A: We can develop it according to your drawing or sample.

5. Q: Why choose CHINAMFG for cooperation?

A: Comparing with our competitors, we have much more advantages as follows:

1. More than 30 years in manufacturing farming machine

2. More Professional Sales staffs to guarantee the better service

3. More agri machines for your choice

4. More New products into your range to avoid price competition

5. Larger quantity production and shipment

6. Better quality to guarantee better Credit.

7. Faster delivery time: Only7days

8. More stick quality checking before shipment.

9. More reasonable after-sales service terms.

10. More famous brand: HONGRI” brand and “CE”ceitification.;SGS certifications

11.Lower repair rate and bad review rate

12. Have received unstinting support from the Chinese government.

If you have any questions, please feel free to contact me.

| Type: | Agriculture Machinery Parts |

|---|---|

| Usage: | Agricultural Products Processing |

| Material: | Carbon Steel |

| Power Source: | Pto Shaft Tube |

| Weight: | 1kg ~10kg |

| After-sales Service: | 12 Months |

| Samples: |

US$ 5/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How do PTO shafts ensure efficient power transfer while maintaining safety?

PTO (Power Take-Off) shafts play a crucial role in ensuring efficient power transfer from a power source to driven machinery or equipment, while also maintaining safety. These shafts are designed with various features and mechanisms to optimize power transmission efficiency and mitigate potential hazards. Here’s a detailed explanation of how PTO shafts achieve efficient power transfer while prioritizing safety:

1. Mechanical Power Transmission: PTO shafts serve as mechanical linkages between the power source, typically a tractor or engine, and the driven machinery. They transmit rotational power from the power source to the equipment, enabling efficient transfer of energy. The mechanical design of PTO shafts, including their diameter, length, and material composition, is optimized to minimize power losses during transmission, ensuring that a significant portion of the power generated by the source is effectively delivered to the machinery.

2. Universal Joints and Flexible Couplings: PTO shafts are equipped with universal joints and flexible couplings that allow for angular misalignment and flexibility in movement. Universal joints accommodate variations in the alignment between the power source and the driven machinery, enabling smooth power transfer even when the two components are not perfectly aligned. Flexible couplings help to compensate for slight misalignments, reduce vibration, and prevent excessive stress on the shaft and connected components, thereby enhancing efficiency and reducing the risk of mechanical failure or damage.

3. Constant Velocity (CV) Joints: CV joints are often used in PTO shafts to maintain constant speed and torque transfer, particularly in applications where the driven machinery requires flexibility or operates at different angles. CV joints allow for smooth power transmission without significant fluctuations, even when the driven machinery is at an angle relative to the power source. By minimizing speed variations and power loss due to changing angles, CV joints contribute to efficient power transfer while ensuring consistent performance and reducing the likelihood of mechanical stress or premature wear.

4. Safety Guards and Shields: Safety is a paramount consideration in the design of PTO shafts. Protective guards and shields are installed to cover the rotating shaft and other moving parts. These guards act as physical barriers to prevent accidental contact with the rotating components, significantly reducing the risk of entanglement, injury, or damage. Safety guards are typically made of durable materials such as metal or plastic and are designed to allow the necessary movement for power transmission while providing adequate protection. Regular inspection and maintenance of these guards are crucial to ensure their effectiveness in maintaining safety.

5. Shear Bolt or Slip Clutch Mechanisms: PTO shafts often incorporate shear bolt or slip clutch mechanisms as safety features to protect the driveline components and prevent damage in case of excessive torque or sudden resistance. Shear bolts are designed to shear or break when the torque exceeds a predetermined threshold, disconnecting the PTO shaft from the power source. This helps prevent damage to the shaft, driven machinery, and power source. Slip clutches work similarly by allowing the PTO shaft to slip when excessive resistance is encountered, protecting the components from overload. These mechanisms act as safety measures to maintain the integrity of the PTO shaft and associated equipment while minimizing the risk of mechanical failures or accidents.

6. Compliance with Safety Standards: PTO shafts are designed and manufactured to comply with relevant safety standards and regulations. Manufacturers follow guidelines and requirements set by organizations such as the American Society of Agricultural and Biological Engineers (ASABE) or other regional safety authorities. Compliance with these standards ensures that PTO shafts meet specific safety criteria, including torque capacity, guard design, and other safety considerations. Users can rely on standardized PTO shafts that have undergone testing and certification, providing an additional layer of assurance regarding their safety and performance.

7. Operator Education and Training: To ensure safe and efficient operation, it is essential for operators to receive proper education and training on PTO shafts. Operators should be familiar with the specific safety features, maintenance requirements, and safe operating procedures for the PTO shafts used in their applications. This includes understanding the importance of using appropriate personal protective equipment, regularly inspecting the equipment for wear or damage, and following recommended maintenance schedules. Operator awareness and adherence to safety protocols significantly contribute to maintaining a safe working environment and maximizing the efficiency of power transfer.

In summary, PTO shafts ensure efficient power transfer while maintaining safety through their mechanical design, incorporation of universal joints and CV joints, installation of safety guards and shields, implementation of shear bolt or slip clutch mechanisms, compliance with safety standards, and operator education. By combining these features and practices, PTO shafts provide reliable and secure power transmission, minimizing power losses and potential risks associated with their operation.

How do PTO shafts enhance the performance of tractors and agricultural machinery?

Power Take-Off (PTO) shafts play a crucial role in enhancing the performance of tractors and agricultural machinery. By providing a reliable power transfer mechanism, PTO shafts enable these machines to operate efficiently, effectively, and with increased versatility. Here’s a detailed explanation of how PTO shafts enhance the performance of tractors and agricultural machinery:

1. Power Transfer: PTO shafts facilitate the transfer of power from the tractor’s engine to various agricultural implements and machinery. The rotating power generated by the engine is transmitted through the PTO shaft to drive the connected equipment. This direct power transfer eliminates the need for separate engines or motors on each implement, reducing complexity, weight, and maintenance requirements. PTO shafts ensure a consistent and reliable power supply, enabling agricultural machinery to perform tasks with optimal efficiency and effectiveness.

2. Versatility: PTO shafts provide tractors and agricultural machinery with increased versatility. Since PTO shafts have standardized dimensions and connection methods, a wide range of implements can be easily attached and powered by the same tractor. This versatility allows farmers to quickly switch between different tasks, such as mowing, tilling, planting, and harvesting, without the need for multiple specialized machines. The ability to use a single power unit for various operations reduces costs, saves storage space, and improves overall operational efficiency.

3. Improved Productivity: PTO shafts contribute to improved productivity in agricultural operations. By harnessing the power of tractors, agricultural machinery can operate at higher speeds and with greater efficiency compared to manual or alternative power methods. PTO-driven implements, such as mowers, balers, and harvesters, can cover larger areas and complete tasks more quickly, reducing the time required to perform agricultural operations. This increased productivity allows farmers to accomplish more within a given timeframe, leading to higher crop yields and improved overall farm efficiency.

4. Reduced Labor Requirements: PTO shafts help reduce labor requirements in agricultural operations. By utilizing mechanized equipment powered by PTO shafts, farmers can minimize manual labor and the associated physical effort. Tasks such as plowing, tilling, and harvesting can be performed more efficiently and with less reliance on human labor. This reduction in labor requirements allows farmers to allocate resources more effectively, focus on other essential tasks, and potentially reduce labor costs.

5. Precision and Accuracy: PTO shafts contribute to precision and accuracy in agricultural operations. The consistent power supply from the tractor’s engine ensures uniform operation and performance of the connected machinery. This precision is crucial for tasks such as seed placement, fertilizer or chemical application, and crop harvesting. PTO-driven equipment can provide consistent rotations per minute (RPM) and maintain the necessary operational parameters, resulting in precise and accurate agricultural practices. This precision leads to improved crop quality, reduced waste, and optimized resource utilization.

6. Adaptability to Various Tasks: PTO shafts enhance the adaptability of tractors and agricultural machinery to perform various tasks. With the ability to connect different implements, such as mowers, seeders, sprayers, or balers, via PTO shafts, farmers can quickly transform their tractors into specialized machines for specific operations. This adaptability allows for efficient utilization of equipment across different stages of crop production, enabling farmers to respond to changing needs and conditions in a cost-effective manner.

7. Enhanced Safety: PTO shafts contribute to enhanced safety in agricultural operations. Many PTO shafts are equipped with safety features, such as shields or guards, to protect operators from potential hazards associated with rotating components. These safety measures help prevent entanglement accidents and reduce the risk of injuries. Additionally, by using PTO-driven machinery, farmers can keep a safe distance from certain hazardous tasks, such as mowing or shredding, further improving overall safety on the farm.

8. Integration with Technology: PTO shafts can be integrated with advanced technology and automation systems in modern tractors and agricultural machinery. This integration allows for precise control, data monitoring, and optimization of machine performance. For example, precision guidance systems can be synchronized with PTO-driven implements to ensure accurate seed placement or chemical application. Furthermore, data collection and analysis can provide insights into fuel efficiency, maintenance needs, and overall equipment performance, leading to optimized operation and improved productivity.

In summary, PTO shafts enhance the performance of tractors and agricultural machinery by enabling efficient power transfer, increasing versatility, improving productivity, reducing labor requirements, ensuring precision and accuracy, facilitating adaptability, enhancing safety, and integrating with advanced technologies. These benefits contribute to overall operational efficiency, cost-effectiveness, and the ability of farmers to effectively manage theiragricultural operations.

How do PTO shafts contribute to transferring power from tractors to implements?

PTO shafts (Power Take-Off shafts) play a critical role in transferring power from tractors to implements in agricultural and industrial settings. They provide a reliable and efficient means of power transmission, enabling tractors to drive various implements and perform a wide range of tasks. Here’s a detailed explanation of how PTO shafts contribute to transferring power from tractors to implements:

Power Source: Tractors are equipped with powerful engines designed to generate substantial amounts of mechanical power. This power is harnessed to drive the tractor’s wheels and operate hydraulic systems, as well as to provide power for the attachment of implements through the PTO shaft. The PTO shaft typically connects to the rear or side of the tractor, where the power take-off mechanism is located. The power take-off derives power directly from the tractor’s engine or transmission, allowing for efficient power transfer to the PTO shaft.

PTO Shaft Design: PTO shafts are designed as driveline components that transmit rotational power and torque from the tractor’s power take-off to the implement. They consist of a hollow metal tube with universal joints at each end. The universal joints accommodate angular misalignments and allow the PTO shaft to transmit power even when the tractor and implement are not perfectly aligned. The PTO shaft is also equipped with a safety shield or guard to prevent accidental contact with the rotating shaft, ensuring operator safety during operation.

PTO Engagement: To transfer power from the tractor to the implement, the PTO shaft needs to be engaged. Tractors are equipped with a PTO clutch mechanism that allows operators to engage or disengage the PTO shaft as needed. When the PTO clutch is engaged, power flows from the tractor’s engine through the power take-off mechanism and into the PTO shaft. This rotational power is then transmitted through the PTO shaft to the implement, driving its working components.

Rotational Power Transmission: The rotational power generated by the tractor’s engine is transferred to the PTO shaft through the power take-off mechanism. The PTO shaft, being directly connected to the power take-off, rotates at the same speed as the engine. This rotational power is then transmitted from the PTO shaft to the implement’s driveline or gearbox. The implement’s driveline, in turn, distributes the power to the implement’s working components, such as blades, augers, or pumps, enabling them to carry out their respective functions.

Matching Speed and Power: PTO shafts are designed to match the rotational speed and power requirements of various implements. Tractors often feature multiple speed settings for the PTO, allowing operators to select the appropriate speed for the specific implement being used. Different implements may require different rotational speeds to operate optimally, and the PTO shaft allows for easy adjustment to match those requirements. Additionally, the power generated by the tractor’s engine is transmitted through the PTO shaft, providing the necessary torque to drive the implement’s working components effectively.

Versatility and Efficiency: PTO shafts offer significant versatility and efficiency in agricultural and industrial operations. They allow tractors to power a wide range of implements, including mowers, balers, tillers, sprayers, and grain augers, among others. By connecting implements directly to the tractor’s power source, operators can quickly switch between tasks without the need for separate power generators or engines. This versatility and efficiency streamline workflow, reduce costs, and increase overall productivity in agricultural and industrial settings.

Safety Considerations: While PTO shafts are essential for power transmission, they can pose safety risks if mishandled. The rotating shaft and universal joints can cause severe injuries if operators come into contact with them while in operation. That’s why PTO shafts are equipped with safety shields or guards to prevent accidental contact. Operators should always ensure that the safety shields are in place and secure before engaging the PTO shaft. Proper training, adherence to safety guidelines, and regular maintenance of PTO shafts and associated safety features are crucial to ensuring safe operation.

In summary, PTO shafts are vital components that enable the transfer of power from tractors to implements in agricultural and industrial applications. They provide a reliable and efficient means of power transmission, allowing tractors to drive various implements and perform a wide range of tasks. By engaging the PTO clutch and transmitting rotational power through the PTO shaft, tractors power the working components of implements, providing versatility, efficiency, and productivity in agricultural and industrial operations.

editor by CX 2023-12-11

China manufacturer Drive Gear Pto and Transmission Shaft Factory Steel Agricultural Machinery Use Power Transmission Shaft Shaft Factory Steel Precision50 with Best Sales

Product Description

Company Profile

HangZhou Xihu (West Lake) Dis. East Port Gear Manufacturing factory is located in Zhoujia Industrial Zone, CZPT Town, HangZhou, 3km away from Xihu (West Lake) Dis.qian Lake. It focuses on precision gear research, development, production and sales. The factory has obtained ISO9001: 2015 certificate, IATF16949:2016. The main export markets were North America, South America and Europe. Products can be customized and mainly includes: New Energy Motor Shaft, Oil Pump Gear, Agricultural Machinery Gear, Transmission Gear, Electric Vehicle gear, etc. We are sincerely willing to cooperate with enterprises from all over the world.

Equipment And Main Products

Certifications

FAQ

Q1:How is the quality of your product?

A:Our product has reliable quality, high wear life

Q2:Customization process/work flow?

Advisory – Material selection – 2D/3D Drawing – Quotation – Payment – Production – Quality Control – Package – Delivery

Q3: What is your terms of packing?

A:Generally, we pack our goods in wooden cases, If you have special request about packing, pls negotiate with us in advance, we can pack the goods as your request.

Q4:Price?

A:We will offer competitive price after receiving your drawing

Q5:What is your terms of payment?

A:30% T/T advanced, 70% T/T before shipping

Q6:What is your terms of delivery?

A: FOB

Q7:What drawing software does your company use?

A:CAXA

Q8:Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q9:How about your delivery time?

A:Product can often be delivered within 40-90 days

Q10:Sample?

A:We offer paid sample.If you have sample requirements, please feel free to contact us at any time

Q11:What logistics packaging does your company use?

A:Express for urgent orders. UPS, FedEx, DHL, TNT, EMS.

Q12:Application range?

A:Automotive, medical, automation, agricultural, marine, etc.

Q13: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them,

no matter where they come from.

Parameter specifications

| Certification | Shipment | Quality | material | Company System Certification |

| IATF16949 | in time | high | steel | ISO9001 |

|

Shipping Cost:

Estimated freight per unit. |

To be negotiated |

|---|

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Agricultural Machinery, Car |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | Internal Gear |

| Samples: |

US$ 50/Piece

1 Piece(Min.Order) | Order Sample 40000

|

|---|

| Customization: |

Available

| Customized Request |

|---|

Power Take-Off (PTO) Shafts

Power take-off (PTO) shafts are used on many types of machines, including jet aircraft. They are typically semi-permanently mounted to a marine or industrial engine, and are powered by a drive shaft. The drive shaft also powers secondary implements and accessories. Depending on the application, accessory drives may also be used in aircraft. There are four main types of PTO units used in jet aircraft.

Power take-off (PTO) shaft

The power take-off (PTO) shaft of a tractor can be controlled to operate in one of two modes: automatic and manual. Automatic mode operates when the PTO shaft starts turning and is automatically engaged when the power lift is raised by actuating the lift lever 9. Manual mode operates when the lift lever is not raised.

The manual mode allows for manual adjustments. A retaining band 12 may be adjusted arcuately about PTO shaft S with an axial center parallel to the axis of the PTO shaft S. The retaining band may be secured by conventional over center clamps. The retaining band 12 may also be adjusted arcuately about pin or bolt 30.

Power take-off (PTO) shaft safety retainers are used to prevent unintended disconnection of the PTO shaft. The safety retainers comprise a stationary openable band that circumscribes the PTO shaft near the connection with driven machinery. The band is preferably offset from the axis of the PTO shaft.

While the PTO shaft is a convenient way to transfer mechanical power to farm implements, there are several inherent hazards associated with using it improperly. Accidental disconnections of the PTO shaft pose a significant risk for the operator. A disconnect can cause the PTO shaft to whip around the driven machinery, potentially causing injury.

Power take-off shaft entanglements can be devastating to the limbs trapped in them, requiring amputation in some cases. In addition to being dangerous, the PTO shafts must be fully guarded to prevent contact with the ground. A farmer must never get too close to an operating PTO shaft to protect their own safety.

Types

There are several different types of PTO shafts available to suit various applications. They can vary in size and number of splines. Each standard has a specific speed range and is designed to fit a variety of implements. For example, there are German and Italian types of PTO shafts.

The type of PTO shaft you choose will determine the maximum load that can be safely transferred. Depending on the type, the rate at which the PTO clutch engages will be different. For example, a lower-density PTO shaft will engage at a slower rate than a higher-density PTO shaft, while a higher-density shaft will be more tolerant of higher loads.

The primary function of a PTO shaft is to secure equipment to the tractor or other agricultural equipment. These parts often feature safety shields on both ends. They are also made in the same shape as the secondary shaft. The front shaft is wider than the secondary shaft, which allows the secondary shaft to fit inside. However, during movement, pieces of the PTO shaft can collapse, making them less safe.

PTO shafts are expensive and easy to steal, so make sure to protect your investment. Make sure the PTO shaft has guards to protect it from thieves. There are two types of PTO shafts: the external and the internal PTO yokes. Internal PTO shafts have an internal PTO yoke, while external PTO shafts use a universal joint. There is also a safety chain and shield on the external PTO shaft.

Depending on the application, you can choose between several different kinds of PTO shafts. Some types of PTO shafts have multiple splines, which can increase the torque transmitted. For applications requiring accuracy and precision, you may want to use a parallel keyed shaft.

Connections

A PTO shaft has two parts: an input and an output. The input portion of a PTO adapter shaft has a smaller diameter, and the output portion has a larger diameter. Both are connected by splines. These splines have tapered outer ends. The first bore 25 has a first frustoconical wall, while the second bore has a second frustoconical wall.

A PTO shaft has two parts: an input and an output. The input portion of a PTO adapter shaft has a smaller diameter, and the output portion has a larger diameter. Both are connected by splines. These splines have tapered outer ends. The first bore 25 has a first frustoconical wall, while the second bore has a second frustoconical wall.

One of the most common causes of PTO shaft failure is a poorly adjusted clutch. Another common cause is improper lubrication of the PTO shaft’s wide angle joints. PTO shafts should be lubricated at least once every eight hours. If you fail to do this, you risk premature ware and reduced life expectancy.

When a PTO shaft is installed in a tractor, the tractor must be connected to the implement using a coupler frame. The coupler frame has a PTO adapter mounting flange that engages with the PTO stub shaft. The coupler frame can move to accommodate the PTO adapter shaft, and the PTO adapter shaft can pivot and slide with the coupler frame.

When a PTO shaft fails, it can result in damage to the tractor and implement. Identifying the cause will help you fix the problem. Constant compression of the PTO shaft can damage the connecting shafts and connections. This could damage the tractor or implement, resulting in expensive repairs. When this happens, it is important to cut or shorten the shaft to reduce the risk of damage.

PTO shaft 24 extends rearward from tractor 10 and is connected to the front universal joint 28 and first end of variable-length splined drive shaft 32. The shaft is connected to a drive mechanism 36 on a mobile work implement 34. This drive mechanism may be mechanical, hydraulic, or a combination of both.

Safety

It is very important for every person using a tractor to understand the safety of PTO shafts. PTOs can be extremely dangerous, and without the correct shielding, they can cause serious injury. It can also be very dangerous if someone accidentally steps on or falls on one while the machine is operating. This is why it is important for everyone using a tractor to read the manufacturer’s manual and follow the safety guidelines for PTO shafts. Moreover, PTOs must only be used for the purpose intended.

PTO safety should be the number one priority for every operator. A small child was tragically killed when he became entangled with a spinning PTO shaft. His father tried to pull him out of the shaft, but was unable to do so. His clothing, which was near the spinning shaft, caught on the PTO and dragged him into it. His body was thrown around the shaft several times, and he sustained injuries to his leg, right arm, and head.

The PTO shaft is an important part of a tractor, and is used to secure the equipment. It is usually secured by safety shields on both ends. There are several kinds of safety shields. One type is a shield that is attached to the front of the PTO shaft. Another type is a shield that rotates freely on its bearings.

Power takeoffs are common on most small and compact tractors, construction machinery, and other equipment. They rotate to provide the drive for the equipment. However, the PTO shaft is very dangerous because it can easily catch something that gets too close to it. Moreover, loose items can also get tangled around the PTO shaft.

Maintenance

One of the most important things to do in order to keep your PTO shaft in top condition is to keep it properly greased. This can be done by using a grease gun or a hand pump. It is important to keep the grease fresh and apply it in the appropriate amounts depending on how much you use the PTO. It is also important to separate the primary and secondary shafts and remove any debris from them.

One of the most important things to do in order to keep your PTO shaft in top condition is to keep it properly greased. This can be done by using a grease gun or a hand pump. It is important to keep the grease fresh and apply it in the appropriate amounts depending on how much you use the PTO. It is also important to separate the primary and secondary shafts and remove any debris from them.

It is also important to check the spline threads on your PTO on a periodic basis. This is important because some signs of dry shafts are not always immediately apparent. Similarly, spline threading and corrosion can occur behind the scenes and go undetected. Proper PTO maintenance is a vital part of safe and efficient operation.

A damaged or worn drive shaft will prevent your car from turning freely, leaving you exposed to higher repair bills. In addition, it will drastically affect the performance of your car. A broken drive shaft can even result in a crash. You should take your vehicle to a mechanic as soon as you notice any of these problems.

Fortunately, most PTO-driven equipment is equipped with a shear pin to prevent collisions and prevent damage to the gearbox and shaft. It should also be replaced regularly to prevent excessive wear. Long bolts pose a risk of entanglement and can easily catch clothing or gloves. For safety reasons, it is important to disengage the PTO when not in use.

Another thing to do is to keep the PTO shields clean. They must be regularly rotated and tested. Always ensure that your drawbar is properly configured for your machine. This prevents stressing or separating the driveline.

editor by CX 2023-06-12

in Merida Mexico sales price shop near me near me shop factory supplier Js Snake Spring Flexible Coupling for Agricultural Machinery manufacturer best Cost Custom Cheap wholesaler

EPG has been productively licensed by ISO9002 Quality Administration Technique, ISO9001 Quality Administration Technique, API certificate, ISO/TS16949:2002 and ISO10012 measurement management method. Entire use has been created of all sorts of innovative methods and technological innovation to reach excelsior manufacturing. a specialised provider of a complete assortment of chains, sprockets, gears, equipment racks, V-belts, couplings and reducers. JS700 Series Grid Coupling

Grid Coupling is extensively utilized in metallurgy, mining, lifting, transportation, petroleum, chemical, ships, textile, ligEPTT business, agricultural EPTTry, printing EPTTs and pumps, followers, compressors, EPTT tools and other mechanical equipment and industry shaft EPTT.

#9830Attribute

one.The serpentine EPT as the elastic aspect, the elastic sturdy at the identical time, tremendously increases the grid coupling torque, broadly utilised in weighty EPTTry and EPTT EPTTry.The serpentine EPT EPTT EPT section, has EPTT provider life, making it possible for higher velocity, has very good potential to compensate in the aXiHu (West EPT) Dis.al, radial and angle

two.EPT EPTT effectiveness, commence protection. EPTT efficiency of up to ninety nine.forty seven%, brief-time overload capacity is two times the rated torque, operation basic safety.

3.Easy framework, hassle-free assembly and disassembly, EPTT services lifestyle

4.Damping result is very good to avoid the resonance.

#9830Basic Parameter And Primary Dimension

| Product | Nominal Torque Nm |

Velocity r/min |

Y,Z Bore done,d2 |

D | B | A | E | N | L | M | P | J | Clearance (K) | Oil EPT Kg |

No bore mass Kg |

|||

| Max | Min | Min | StXiHu (West EPT) Dis.Hu (West EPT) Dis.rd | Max | ||||||||||||||

| JS702 | a hundred twenty five | 10000 | 35 | fourteen | one hundred twenty | 107 | fifty | 80 | 80 | 52 | 78 | 27 | fifty | one.five | three | 5 | .03 | eight |

| JS704 | 400 | 9000 | 48 | fourteen | one hundred sixty | 127 | 65 | a hundred and five | one zero five | sixty two | ninety five | 36 | 60 | one.5 | three | five | .03 | 11 |

| JS706 | 900 | 8200 | 65 | 19 | 185 | 167 | ninety | one hundred twenty five | 130 | 82 | one hundred and five | 50 | sixty five | one.five | three | 5 | .06 | 12 |

| JS707 | 1800 | 7100 | seventy five | 28 | 218 | 228 | a hundred and five | one hundred fifty | 156 | 112 | 135 | 52 | 86 | 1.five | four | six.five | .06 | fifteen |

| JS708 | 3150 | 6000 | eighty five | 28 | 245 | 228 | one hundred twenty five | one hundred eighty | 175 | 112 | a hundred forty five | fifty eight | ninety two | 1.5 | 4 | 6.5 | .09 | 20 |

| JS709 | 5600 | 4900 | one hundred | 42 | 286 | 290 | 140 | 210 | 208 | 142 | a hundred and eighty | 70 | 118 | 1.5 | six | ten | .09 | 25 |

| JS710 | 8000 | 4500 | one hundred ten | 42 | 325 | 290 | 160 | 245 | 230 | 142 | 190 | 74 | a hundred twenty five | one.five | six | 10 | .17 | 33 |

| JS711 | 12500 | 4000 | 125 | 60 | 330 | 290 | one hundred eighty | a hundred and eighty | 258 | 142 | 220 | 85 | one hundred fifty | one.five | six | 13 | .26 | fifty seven |

| JS712 | 18000 | 3600 | one hundred fifty | 70 | 365 | 351 | 220 | 220 | 295 | 172 | 225 | ninety five | one hundred fifty | one.5 | 6 | 13 | .43 | eighty |

| JS713 | 26000 | 3300 | a hundred and eighty | 70 | 420 | 351 | 255 | 255 | 335 | 172 | 235 | 115 | 156 | one.five | 6 | 13 | .51 | 97 |

#9830Product Present

#9830Other EPT Listing

| EPTT EPTTry Parts Name |

Design |

| EPT Coupling | WS,WSD,WSP |

| Cardan Shaft | SWC,SWP,SWZ |

| Tooth Coupling | CL,CLZ,GCLD,GIICL, GICL,NGCL,GGCL,GCLK |

| Disc Coupling | JMI,JMIJ,JMII,JMIIJ |

| EPT FleXiHu (West EPT) Dis.ble Coupling | LM |

| EPTT Coupling | GL |

| Jaw Coupling | LT |

| Grid Coupling | JS |

#9830Our EPTT

Our business provides various varieties of products. EPT top quality and sensible price tag. We stick to the basic principle of quotquality 1st, provider first, continuous improvement and innovation to meet the buyers quot for the management and quotzero defect, zero grievances quot as the high quality aim. To excellent our services, we give the items with great quality at the reasonable price.

Welcome to customize merchandise from our manufacturing unit and you should offer your design and style drawings or get in touch with us if you want other requirements.

#9830Our Services

one.Style Providers

Our design and style crew has knowledge in cardan shaft relating to item layout and deveXiHu (West EPT) Dis.Hu (West EPT) Dis.ment. If you have any wants for your new merchandise or wish to make even more advancements, we are below to supply our support.

two.Solution Solutions

raw materials #8594 Reducing #8594 EPT #8594Rough machining #8594Shot blasting #8594Heat treatment #8594Testing #8594Fashioning #8594Cleaning #8594 Assembly #8594EPTT #8594EPT

3.Samples Treatment

We could deveXiHu (West EPT) Dis.Hu (West EPT) Dis. the sample according to your need and amend the sample continuously to satisfy your need to have.

four.EPT amp DeveXiHu (West EPT) Dis.Hu (West EPT) Dis.ment

We normally analysis the new wants of the marketplace and deveXiHu (West EPT) Dis.Hu (West EPT) Dis. the new product when there is new autos in the market.

five.EPTT EPTT

Every action need to be EPTT take a look at by Expert Workers according to the stXiHu (West EPT) Dis.Hu (West EPT) Dis.rd of ISO9001 and TS16949.

#9830FAQ

Q 1: Are you investing business or producer?

A: We are a specialist maker EPTTizing in producing

various sequence of couplings.

Q 2:Can you do OEM?

Of course, we can. We can do OEM amp ODM for all the buyers with EPT artworks of PDF or AI structure.

Q three:How EPTT is your supply time?

EPTTly it is twenty-30 daEPTTif the items are not in inventory. It is according to amount.

Q four: Do you give samples ? Is it free or further ?

Indeed, we could provide the sample but not for free of charge.In fact we have a extremely very good price basic principle, when you make the bulk orEPTTthen EPT of sample will be deducted.

Q five: How EPTT is your warranty?

A: Our Guarantee is 12 thirty day period unEPTTnormal circumstance.

Q 6: What is the MOQ?

A:Normally our MOQ is 1pcs.

Q seven: Do you have inspection processes for coupling ?

A:a hundred% self-inspection just before EPTT.

Q 8: Can I have a check out to your manufacturing facility ahead of the order?

A: Certain,welcome to pay a visit to our manufacturing facility.

Q nine: What is your payment?

A:1) T/T. 2) L/C

#9830Speak to Us

World wide web:

Add: No.one HangEPT Highway,CXiHu (West EPT) Dis.Hu (West EPT) Dis. park,EPTTgEPTTng EPTT,EPTTngsu Province,EPTT

Best sales made in China – replacement parts – PTO shaft manufacturer & factory Agricultural shortening pto shaft Machinery Rotary Tiller with ce certificate top quality low price

We – EPG Team the largest agricultural gearbox and pto manufacturing unit in China with 5 diverse branches. For far more information: Cell/whatsapp/telegram/Kakao us at: 0086-13083988828

pto adapter Principal pto shaft for bush hog tractor source products tata nano generate shaft contain: 2003 honda crv travel shaft manure bush hog slip clutch disc spreading john deere pto shaft modify truck, are all pto shafts the identical size potato bush hog end mower rdth60 planting/harvesting pto hydraulic pump with output shaft machine, tractor pto shaft tubing disc plough, disc harrow, grass Mower/slasher, corn and wheat thershers, seeder, mouldboard plow, deep subsoiler machines, rotary tiller, rear blade, fertilizer spreader, blend rice harvester, corn thresher, farm trailer, ridger, trencher, stubble cleaner, earth auger, cultivator and its equipment: Plow disc blades, harrowing film, plough suggestion and share, cultivator tine, casting parts and so on. Our manufacturing facility has obtained the certificate of China’s Farm Equipment Items Good quality Authentication promulgated by the Farm Equipment Goods Good quality Authentication Centre of China. Details:

The Rotary tiller is EPT for cultivating,aerating andstirring up soil for garden,foodstuff plots and other tillage needs.

*Performs on 20-90HP Tractors.

*Oil bathtub iubrication with all gear-driven driveline.

*Self-sharpening warmth-dealt with tines.

*Adju EPT runners for operating depths from 1 in.to 7 in.

*Arrive with hefty-responsibility PTO shaft and slip clutch.

Can perform on dry land/paddy field for ploughing, harrow, slicing stubble at very first plunging, weeding at cultivation, flatting at deep ploughing, generating plasm at paddy area, flatting subject surface area, mixing soil for road building

Adopts big gears for regular transmission and prolonged time use

EPT double bearing composition tends to make it lighter and expend much less electrical power

Requirements:

| Model | Blade | Blade Type | Shaft |

| GQN-a hundred twenty five | 26 | IT225 | 6*six |

| GQN-one hundred forty | 32 | IT225 | six*6 |

| GQN-a hundred and fifty | 36 | IT245 | 6*eight |

| GQN-one hundred sixty | 40 | IT245 | eight*8 |

| GQN-a hundred and eighty | fifty two | IT245 | 8*8 |

| GQN-220 | 62 | IT265 | 8*8 |

| GQN-240 | sixty four | IT265 | eight*8 |

Photographs for delivery

Best shop made in China – replacement parts – PTO shaft manufacturer & factory Densen pto shaft with cv joint Customized China Transmission Shaft Coupling, Coupling of Agricultural Machinery Accessories with ce certificate top quality low price

We – EPG Group the greatest agricultural gearbox and pto manufacturing unit in China with 5 various branches. For far more specifics: Cell/whatsapp/telegram/Kakao us at: 0086-13083988828

xj sye driveshaft We 2001 crv drive shaft warmly common pto shaft defend welcome taking away pto shaft kubota the ford 4000 tractor pto elements close friends 300zx a single piece driveshaft from hyundai eon front axle price all gkn driveshaft the ford figo generate shaft planet! continuous velocity joint pto shaft Underneath the assistance of managerial perception of “Serving agriculture, scoring a accomplishment by way of top quality of goods and honesty in business”, our merchandise have been trusted by consumers and have gained a greater share of marketplace.

Densen personalized china transmission shaft coupling,coupling of agricultural equipment components

| Product Identify | Densen personalized china transmission shaft coupling,coupling of agricultural machinery add-ons |

| DN mm | sixteen~190mm |

| Rated Torque | 40~25000 N·m |

| Allowable velocity | 4500~200 kN·m |

| Substance | forty five#steel |

| Software | Extensively utilised in metallurgy, mining, engineering and other fields. |

Solution display

Organization Data

Equipment

Software Scenario

Common circumstance of diaphragm coupling applied to variable frequency velocity control tools

JMB sort coupling is utilized to HangZhou Oilfield Thermal Energy Plant

In accordance to the requirements of HangZhou Electric Energy Corporation, HangZhou Oilfield Thermal Power Pl EPT need to dynamically modify the electricity generation according to the load of the power grid and marketplace demand from customers, and carry out the transformation of the frequency converter and the suction supporter. The motor was at first a 1600KW, 730RPM non-frequency variable pace motor matched by HangZhou Motor Factory. The pace handle mode right after modifying the frequency is manual handle. Push the button velocity to boost 10RPM or drop 10RPM. The coupling is even now the original elastic decoupling coupling, and the elastic de-coupling coupling following frequency conversion is frequently broken, which immediately influences the regular electrical power generation.

It is found through evaluation that in the process of frequency conversion pace regulation, the pin of the coupling can not bear the inertia of the speed regulation procedure (the diameter of the admirer impeller is 3.3 meters) and is lower off, which has wonderful injury to the motor and the admirer.

Later on, they switched to the JMB460 double-diaphragm wheel-kind coupling of our manufacturing facility (patent amount: ZL.99246247.9). Soon after 1 hour of harmful experiment and a lot more than a single calendar year of procedure examination, the products is operating extremely effectively, and there is no Replace the diaphragm. 12 units have been rebuilt and the procedure is in good situation.

Other Software Scenario

Spare parts

Packaging & Delivery

Make contact with us

High qualtiy best price Agricultural machinery transmission belt pulley PCM-10.01.39.111 for Harvester Parts supplier factory manufacturer & exporter in China

Overview

Quick Details

Applicable Industries: :

Manufacturing Plant

Place of Origin:Zhejiang, China Brand Name: :

OEM

Product name: :

belt pulley for Harvester Parts

Application: :

Power Transmission

Certificate: :

ISO9001:2008

Size: :

24*24*5cm

Weight: :

4kg

MOQ: :

6pc

Every process, every section, every function in EPG is demanded to be done one step following another, carefully and cautiously, from material selection, reformation to manufacturing accessories, from components heat treatment to automatic assembly, from quality control to product inspection and testing and from order dealing to after sales service. Packing: :

Carton Packing

OEM: :

PCM-10.01.39.111

Quality Control: :

High-quality

Standard: : We’ve built up our product range to respond to the vastly different conditions found in different industrial environments around the world. From heavy industry to precision manufacturing, we work with end-users in almost every industry and have specialist solutions which are proven to offer a distinct performance advantage for your application.

ISO TUV Standard

Supply Ability

Supply Ability: : 100 Piece/Pieces per Month

Packaging & Delivery

Packaging Details: 3pc carton packing Port: Tianjin xingang port, Lianyungang port. Yiwu port, Shanghai Due to our wide product range and rich experiences in this industry, we are confident to provide our customers flexible and diversified services. Lead Time : :

| Quantity(Bags) | 1 – 50 | 51 – 100 | >100 |

| Est. Time(days) | 7 | 15 | To be negotiated |

Online Customization

HangZhou EPG TransmissionCo., Ltd

8 Years+ Production Experience

Agricultural machinery transmission belt pulley PCM-10.01.39.111 for Harvester Parts

| Applicable Industries | Machinery Repair Shops,Farms |

| Type | Round Belt |

| Material | Steel |

| Place of Origin | China |

| China | Xinjiang |

| Brand Name | EP |

| Product name | belt pulley for Harvester Parts |

| Application | Power Transmission |

| Certificate | ISO9001:2008 |

| Size | 24*24*5cm |

| Weight | 4kg |

| MOQ | 6pc |

| Packing | Carton Packing |

| OEM | PCM-10.01.39.111 |

| Quality Control | High-quality |

| Standard | ISO TUV Standard |

Q1:How your company usually transports goods to your countries?

This problem is mainly determined by the quantity of the goods. If the number of orders is sufficient for a container, it is recommended that containers be shipped by sea or rail; if the number of orders is small, they can be shipped by the shipping company.

Q2:Is your company’s products retailable?

Sorry, we do not accept retail orders. Our order quantity is determined according to the packaging of the goods. For example, if there are 30 cases in one box, then 30 are the lowest order quantity.

Q3:What is the payment method?

If it is a spot, we need to receive the full payment before they can be shipped; if it is an order, then according to the prepaid 30%, the remaining 70% of the payment before the contract to sign the contract.